Plastic Injection Molding

Outlook for the Medical Plastics Market in 2020

While it’s impossible to predict every fluctuation in commercial and industrial markets, there are plenty of predictions for where the plastic medical market is heading in 2020. With shifts in global manufacturing and a spike in the demand for medical equipment, supplies and devices, the plastic medical market is expected to grow as the year…

Read MoreSwitching Your Injection Molder? Consider These First.

Thinking about switching injection molders? We know it’s not a decision to take lightly. Fortunately, most businesses find themselves in this position only rarely. Unfortunately, it’s often due to a deterioration of the OEM and contract manufacturer’s working relationship. Perhaps costs have been on the rise, perhaps you’ve experienced a rise in quality issues, no…

Read MoreWhat’s Next for Injection Molding

With another year making its way out the door, it’s a great time to reflect on where our industry is heading. Below are a few of the trends we believe will affect plastics professionals and consumers in the months ahead. The Search Continues for Lighter Weight Parts While not exactly a new trend, the search continues…

Read MoreHow Long Can I Expect My Injection Mold to Last?

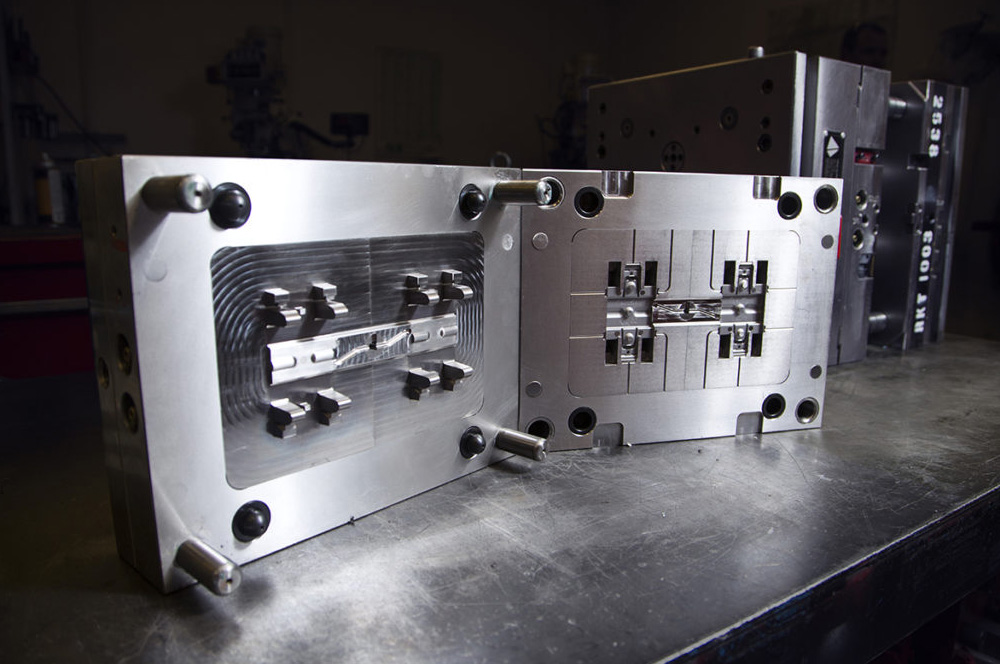

As anyone who has gone through manufacturing before knows, injection molds are one of the most expensive investments you will make as you prepare to bring new products to market. An injection mold can easily cost upwards of tens to hundreds of thousands of dollars, depending on the complexity of the mold and the materials…

Read MoreEverything You Need to Know About Multi-Cavity Injection Molds

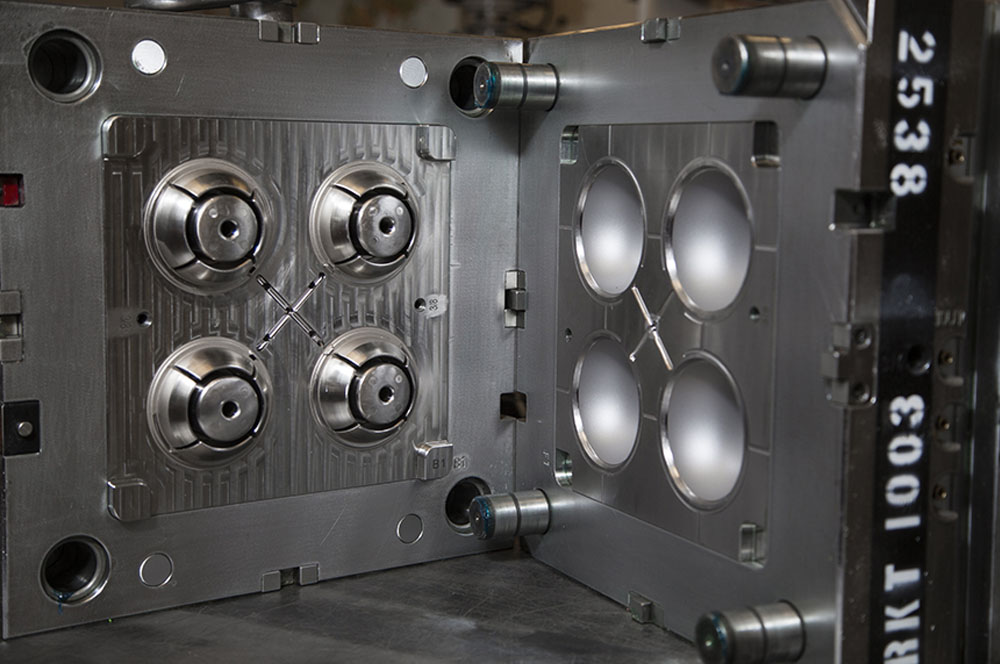

A multi-cavity injection mold is, as the name implies, an injection mold that has more than one cavity. Each of those cavities is the same. The mold is designed to produce multiples of the same part during each production run. Multi-cavity injection molds are often used for higher volume products since it means each production…

Read MoreTips to Help You Design More Affordable Products

Managing Profitability The key to manageable business growth and increased profitability is to maintain healthy margins, but you might find that the amount you spend on manufacturing is throwing your profitability out of whack. Depending on what you’re manufacturing, the types of materials you’re using, and the scale of your operation some manufacturing costs might…

Read MoreHow We Can Make Injection Molding More Sustainable

If you use injection molding to produce plastic parts and components, it’s important to consider the ways in which your production affects the environment and what you can do to minimize the effects it has on the world around you. Here are just a few of the ways we can work together to make injection…

Read MoreInjection Molding for Recreational Outdoor Products

Since injection molding processes were first developed, they have become increasingly popular for applications across just about every industry. One industry, in particular, that’s been revolutionized by the advent of advanced injection molding technology is outdoor recreation. There are a lot of factors that have contributed to the success of injection molding for outdoor products.…

Read MoreTRENDS AFFECTING THE PLASTICS INDUSTRY IN 2019

As any new year begins, people speculate about what to expect in the coming months. Here are some of the trends affecting the plastics industry in 2019. Growth in automotive end-use applications: While injection molding has traditionally been utilized to create parts and components for machinery, equipment and industrial applications, we expect to see demand growing…

Read MoreSTRUCTURAL FOAM MOLDING VS. TRADITIONAL INJECTION MOLDING

Injection molding has been an important manufacturing process for decades. The process can be used to make a wide variety of products rapidly and on a large scale. Most manufacturers and product developers understand the benefits of using plastic injection molding for their parts, components, and products, but lots of people don’t know how many…

Read More

Molding services for Agricultural customers

Molding services for Agricultural customers