Injection Mold Design

What is Moldability, and Why Does it Matter?

As you’re preparing your product designs for injection molding, you may hear your manufacturing team talking about the moldability of the design. But what is moldability? And why is it so important? Merriam-Webster has a simple answer. Moldability, according to Webster, is simply “the property of being moldable”. Ok, then. The longer version of that…

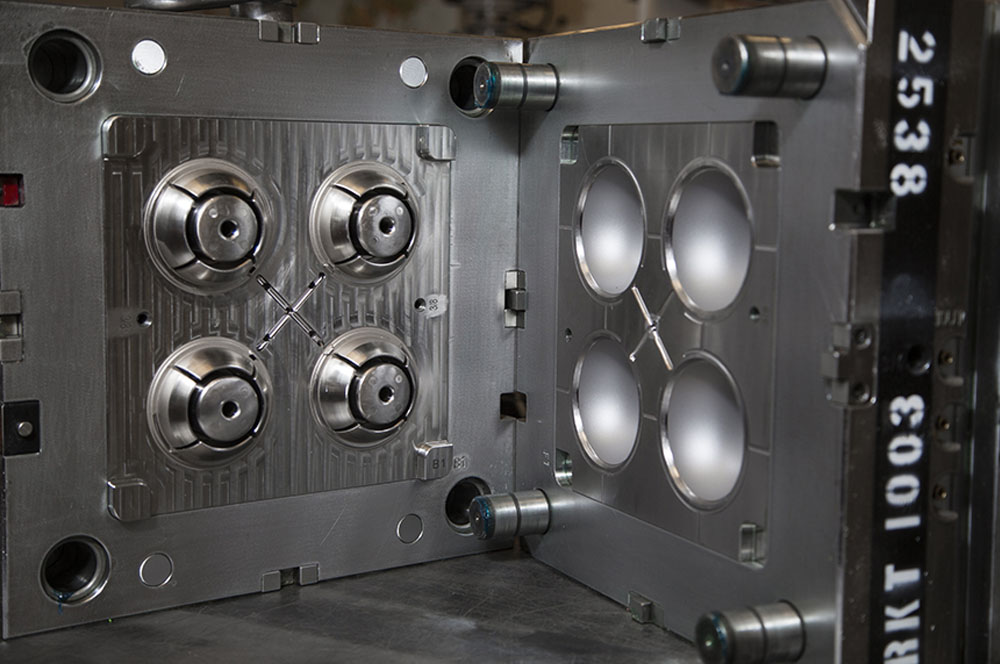

Read MoreEverything You Need to Know About Multi-Cavity Injection Molds

A multi-cavity injection mold is, as the name implies, an injection mold that has more than one cavity. Each of those cavities is the same. The mold is designed to produce multiples of the same part during each production run. Multi-cavity injection molds are often used for higher volume products since it means each production…

Read MoreMost Common Injection Molding Defects (and How to Avoid Them)

Designing injection molded products is not for the faint of heart. There are many things that can – and sometimes do – go wrong that can negatively affect your production and, ultimately, the quality of your finished parts. Below, we take a look at some of the more common defects as well as steps you…

Read MoreInjection Mold Design Rules that Will Make Your Life a Whole Lot Easier

To produce an injection molded part that is structurally sound, functional and efficient, you need to start with good design. Many factors come into play during the design and engineering process, and it’s important for manufacturers to consider these things carefully to ensure the success of their part. While there isn’t a single formula for…

Read MoreTOP DESIGN CONSIDERATIONS FOR INJECTION MOLDING

Injection molding can be a great choice to create a wide variety of products. When it comes to injection molded products, the possibilities are virtually endless, but it’s essential to take some key factors into consideration during the design and development of your product to ensure the best possible end results. Wall thickness: One of the…

Read MoreWHAT FACTORS AFFECT THE PRICE OF AN INJECTION MOLD?

When you’re developing an injection molded part, there are a lot of factors to take into consideration. One of the most important things to consider is the price of your injection mold. This is dependant on a wide variety of different factors and it can fluctuate significantly depending on how those factors vary. Understanding the…

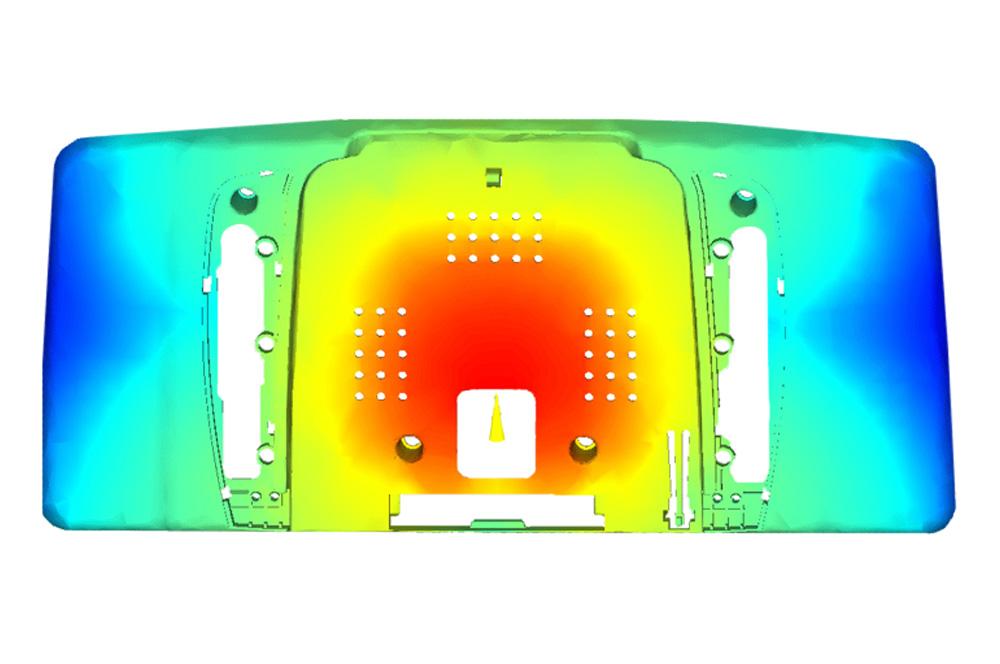

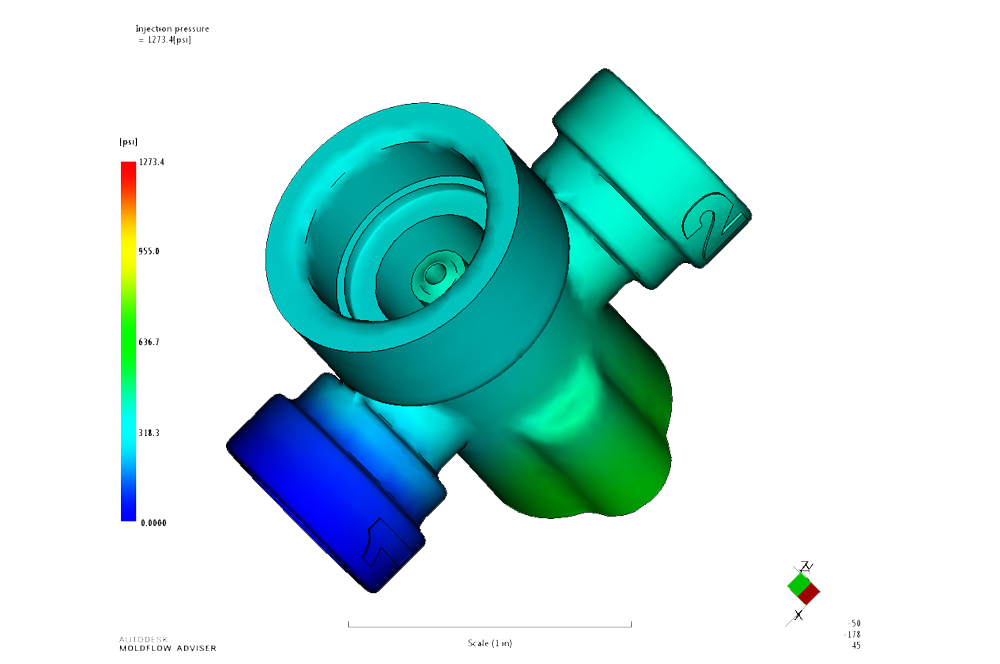

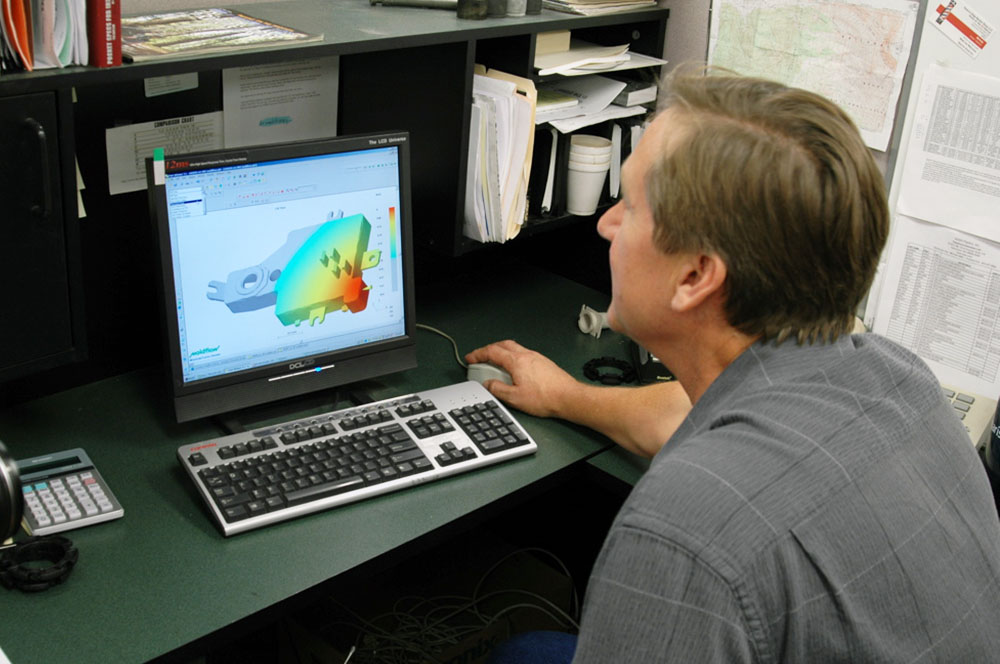

Read MoreIS MOLD FLOW ANALYSIS THE RIGHT CHOICE FOR ALL PROJECTS? HERE ARE A FEW THINGS TO CONSIDER.

Injection molding has advanced over the last few decades and the injection molding process continues to evolve and improve. One of the more important tools used in modern injection molding design is mold flow analysis. Mold flow analysis allows us to assess a mold’s design to ensure that it will deliver all of the strength,…

Read MoreDESIGN TIPS TO HELP YOU CREATE STRONG PLASTIC PARTS

When you design and develop a product, you want to ensure that it meets the highest standards of quality, efficiency and durability possible while minimizing production time and costs. Unfortunately, maintaining this balance between quality and cost-effectiveness isn’t always easy. The good news is that there are several things you can do to improve your…

Read MoreTIPS FOR SUCCESSFUL INJECTION MOLD DESIGN

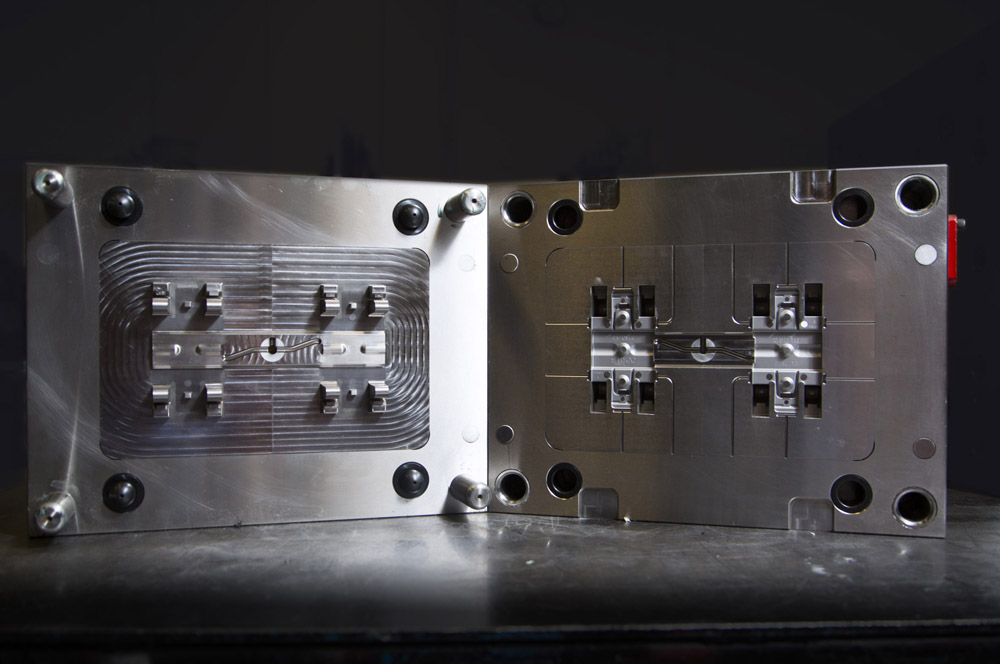

Injection molding isn’t a simple process, and as many of us know, it can sometimes take quite a bit of trial and error to get your injection molding designs just right. And while every new design requires several iterations between initial conception and production, there are several things you can do now to increase the…

Read MoreWHY ARE INJECTION MOLDS SO EXPENSIVE?

First-time product designers, we understand that the first look you get at how much your new product’s injection mold is going to cost can be… impactful. After all, the injection mold is the most expensive element of any new product launch. But why? Why are injection molds so dang expensive? INJECTION MOLD DESIGN AND TOOLING…

Read More

Molding services for Agricultural customers

Molding services for Agricultural customers