Posts Tagged ‘injection mold design’

5 TIPS TO MINIMIZE CYCLE TIME DURING INJECTION MOLDING

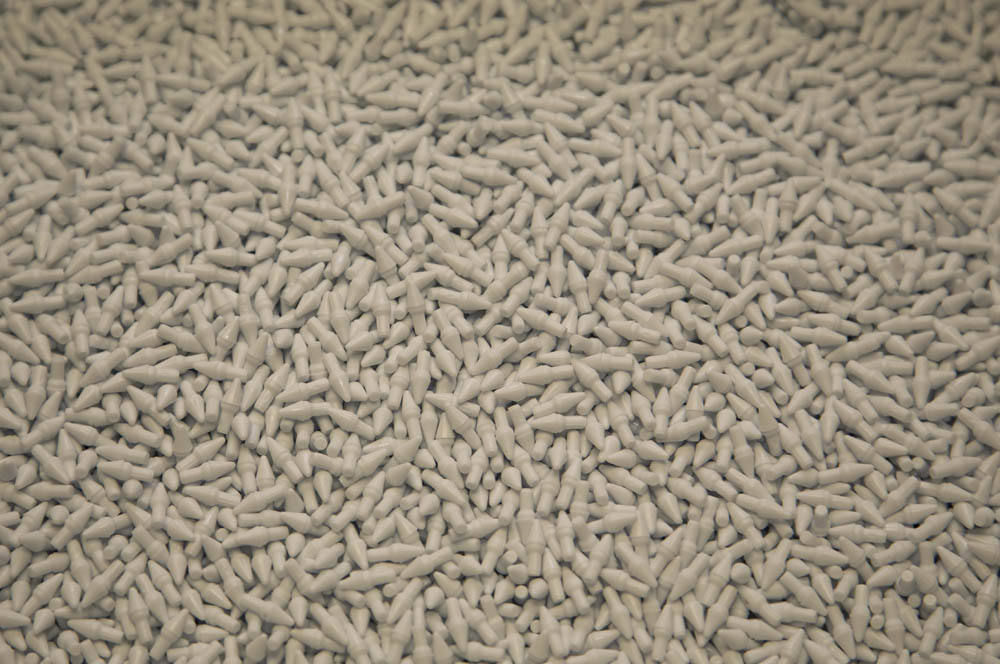

You’re probably familiar with the old adage ‘time is money,’ but if you’re like most of us you might have a harder time actually putting this principle into practice. Cutting down cycle times, even fractionally, can be a challenge and it often requires a significant amount of trial and error to successfully reduce manufacturing time…

Read MoreWHAT YOU NEED TO KNOW ABOUT INJECTION MOLD MAINTENANCE

If you have a car, you already know the best way to prevent major issues is to invest in regular care and maintenance. This same principle holds true when it comes to your injection molds. These tools are not only expensive, but will also be used over and over again. Therefore, preventative maintenance on a…

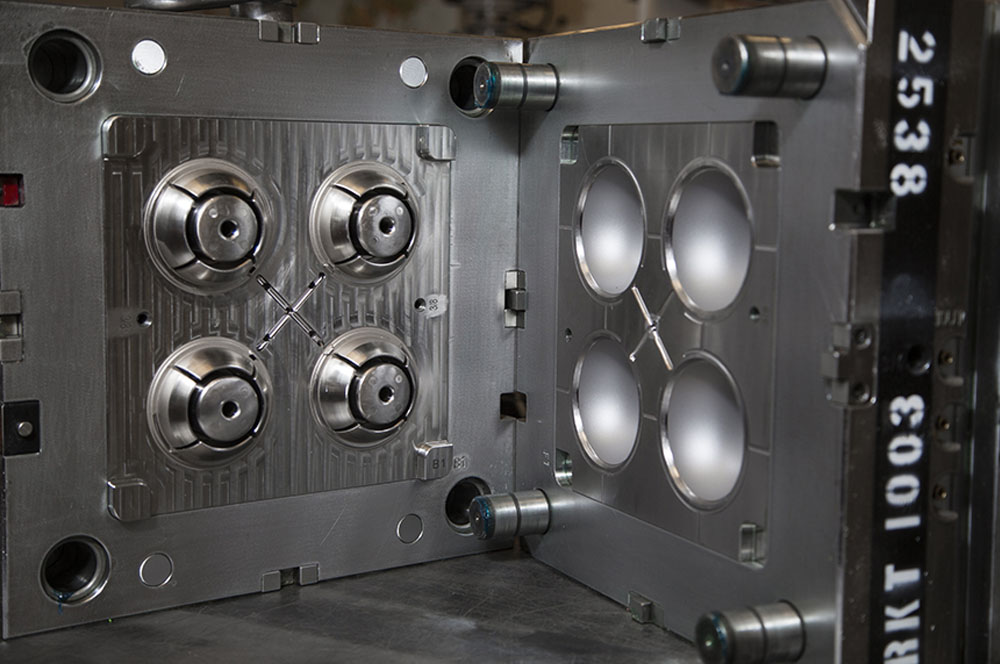

Read MoreWHY ARE INJECTION MOLDS SO EXPENSIVE?

First-time product designers, we understand that the first look you get at how much your new product’s injection mold is going to cost can be… impactful. After all, the injection mold is the most expensive element of any new product launch. But why? Why are injection molds so dang expensive? INJECTION MOLD DESIGN AND TOOLING…

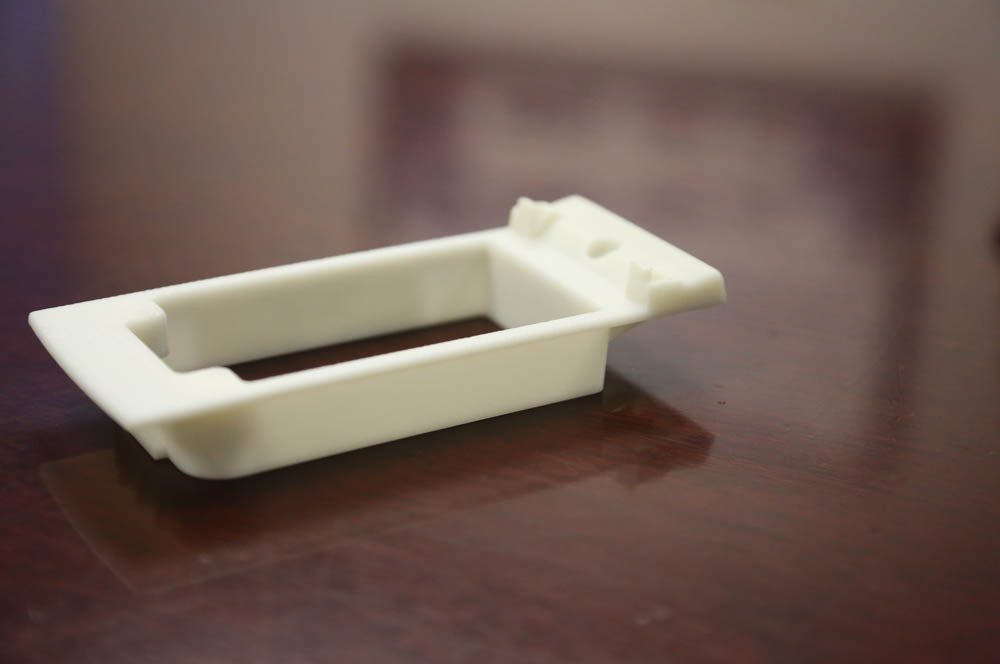

Read More3D PRINTED INJECTION MOLDS: A NEW WAY TO TEST PRODUCT DESIGNS

3D PRINTED PROTOTYPES 3D printing has long been used to create prototypes that can test out product designs to ensure the fit and function of new parts, but recently it’s been gaining steam as an effective tool for creating injection molds as well. 3D PRINTED INJECTION MOLDS What is there to be gained by using…

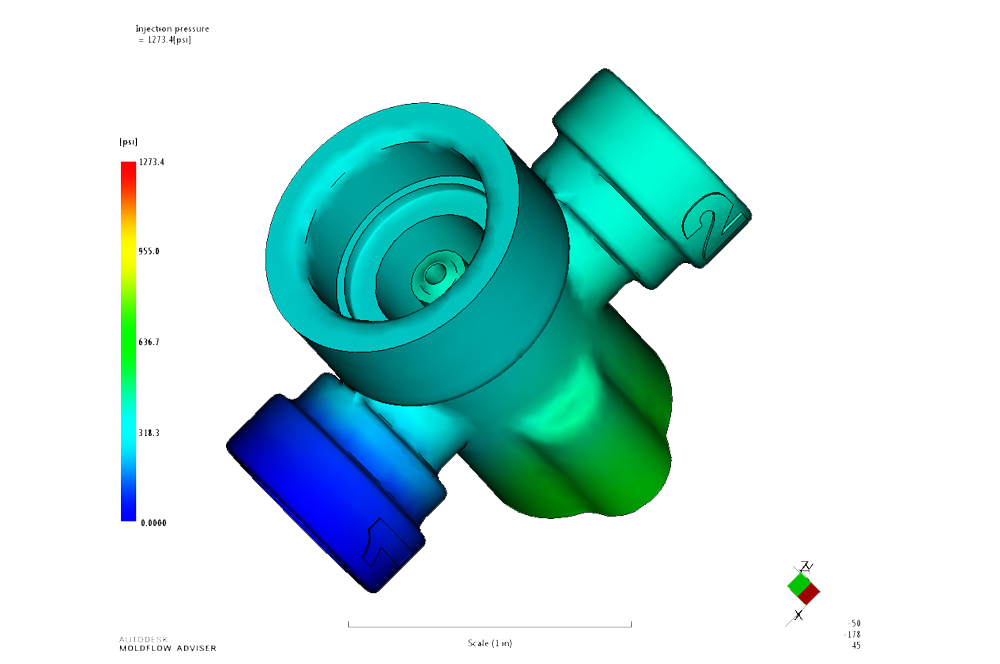

Read MoreIS MOLD FLOW ANALYSIS THE SECRET TO QUALITY INJECTION MOLDED PRODUCTS?

When it comes to injection mold manufacturing, the old adage that time is money has never been more true. On an increasingly competitive international stage, the ability to bring products to market on-time and on budget can often mean the difference between becoming a market leader and trying to play catch up against the competition.…

Read More

Molding services for Agricultural customers

Molding services for Agricultural customers