Posts Tagged ‘lightweighting’

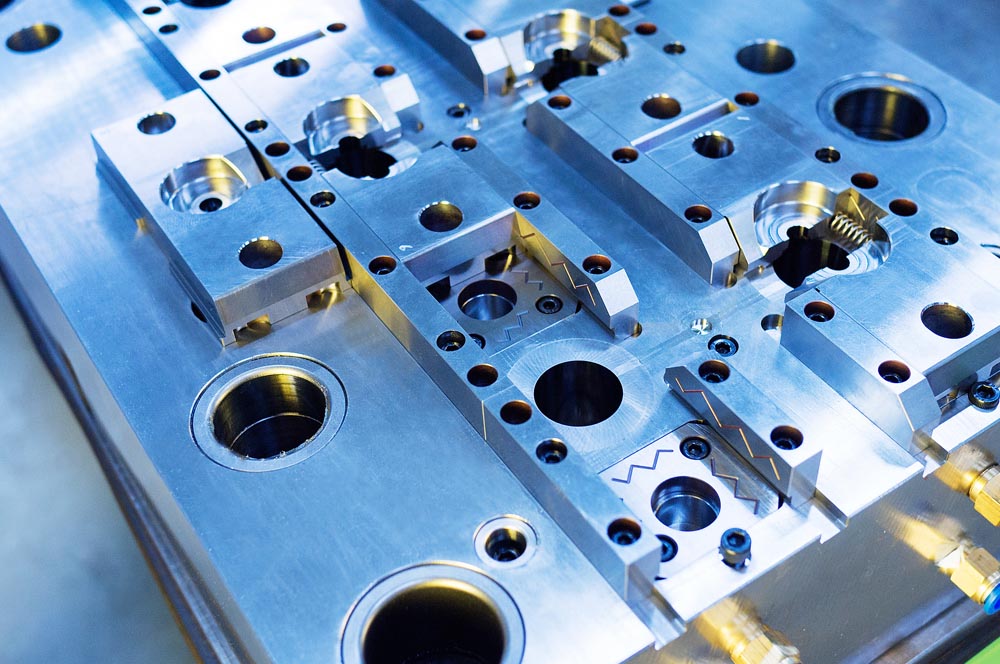

LIGHTWEIGHTING BRINGS NEW OPPORTUNITIES FOR METAL TO PLASTIC CONVERSION

2025 may seem like a long ways off for some of us, but for automotive manufacturers around the U.S., it’s only a few product design cycles away from reality. That’s a scary thought for some, as 2025 happens to be when the Corporate Average Fuel Economy reaches 54.5 miles per gallon. Lightweighting is one method…

Read MoreDESIGNERS TURN TO PLASTICS TO LIGHTEN LOAD FOR AUTOMOTIVE PARTS

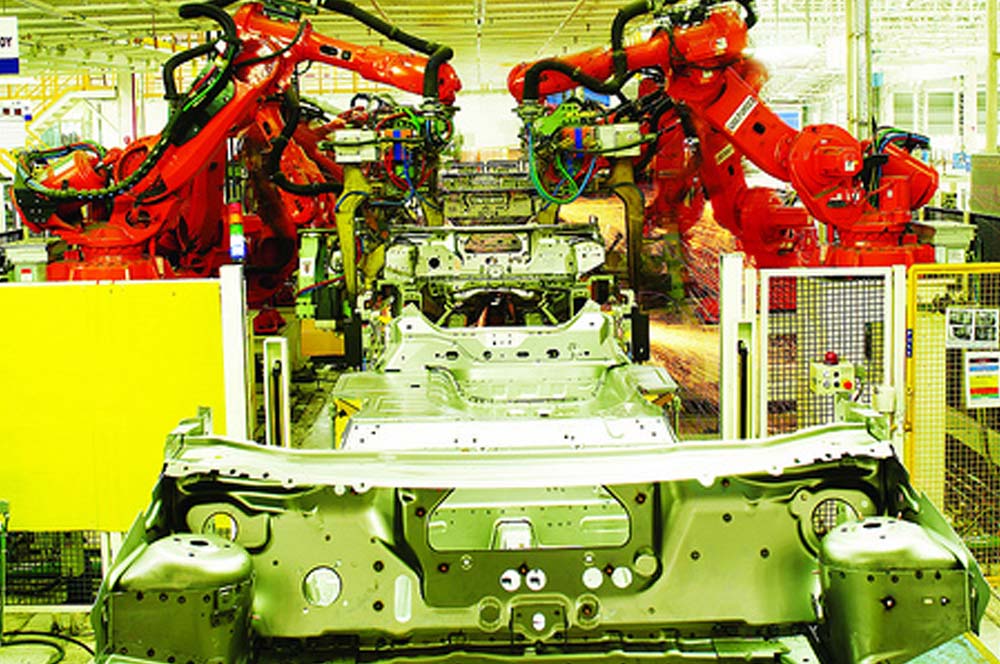

A November conference held in Livonia, Michigan highlighted a recent shift towards plastics in automotive part design and manufacturing. The move results in large part from growing government and consumer demand for automotive vehicles offering better emissions control and miles per gallon as well as overall product durability. In a recent post from Plasticsnews.com, it was…

Read MoreAUTOMOTIVE OEMS TURN TO STRUCTURAL FOAM MOLDING TO REDUCE WEIGHT AND PRODUCTION COSTS

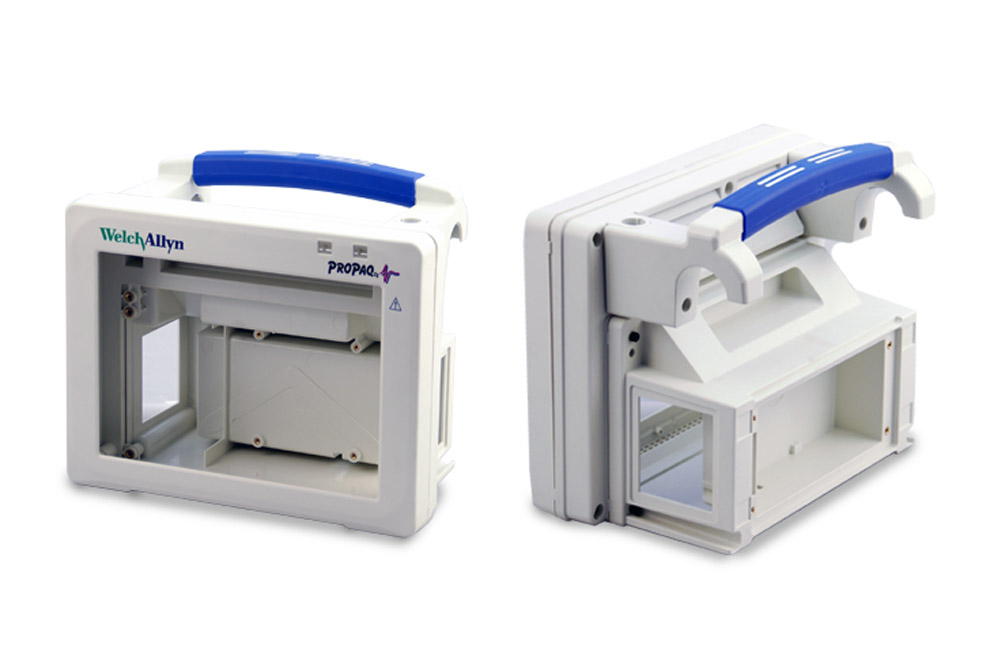

STRUCTURAL FOAM MOLDING AND AUTOMOTIVE LIGHTWEIGHTING Automotive OEM manufacturers are finding themselves turning to structural foam molding in their continued quest to “lightweight” their automotive parts, hoping to reduce both weight and manufacturing costs via the low pressure traditional plastic injection molding alternative. Automotive manufacturers have been exploring the use of plastic parts in order…

Read MoreDESIGNERS TURN TO PLASTICS TO LIGHTEN LOAD FOR AUTOMOTIVE PARTS

A November conference held in Livonia, Michigan highlighted a recent shift towards plastics in automotive part design and manufacturing. The move results in large part from growing government and consumer demand for automotive vehicles offering better emissions control and miles per gallon as well as overall product durability. In a recent post from Plasticsnews.com, it…

Read More

Molding services for Agricultural customers

Molding services for Agricultural customers