Posts Tagged ‘materials selection’

CONSIDERATIONS FOR MATERIAL SELECTION

WHAT YOU NEED TO KNOW ABOUT MATERIAL SELECTION Material selection is aided by answering a few key questions about your product, so you can begin to narrow down your options. What will the product be used for? Is it going to get banged around, or is it mostly for a cosmetic application? How the part…

Read MoreFACTORS THAT AFFECT THE MATERIAL SELECTION PROCESS

As you’re designing new parts, there are a variety of different factors that you’ll need to consider to prepare for production. One of the most important decisions you’ll make during product development is what kind of material you’ll use for your part. This isn’t always a simple choice; there are a lot of different factors…

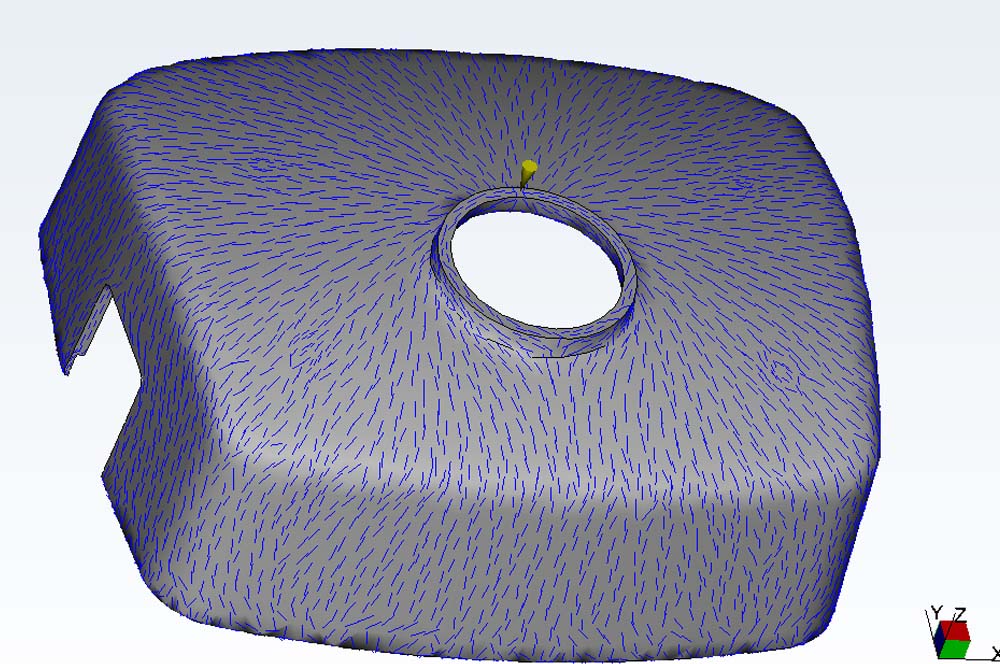

Read More5 THINGS TO CONSIDER IN THE DESIGN FOR MANUFACTURING REVIEW

THE DESIGN FOR MANUFACTURING REVIEW The Design for Manufacturing review is intended to maximize the quality and performance of your parts and help you control your production costs. This is helpful for large and small-scale manufacturing alike, and is most effective in the beginning stage of product design and production. DFM allows you to improve…

Read MoreSO WHY IS MATERIAL SELECTION SO IMPORTANT, ANYWAY?

When it comes to your plastic parts, you hear a lot about the importance of material selection. And, while it can seem confusing at first, the truth is proper material selection can make a BIG difference for your products. Here’s why. DIFFERENT MATERIALS, DIFFERENT COSTS Now you might be thinking surely there are plenty of…

Read More‘DESIGN FOR MANUFACTURING’ TURNS GREAT PRODUCT DESIGNS INTO SUCCESSFUL FINISHED PRODUCTS

DESIGN FOR MANUFACTURING: A CRUCIAL STEP TOWARDS PRODUCT SUCCESS Design for Manufacturing is a crucial element of any successful push towards launching new products, ensuring designs are optimized for the manufacturing process. That’s because no matter how brilliant a design is, certain production constraints can take a promising design and turn it upside down fast.…

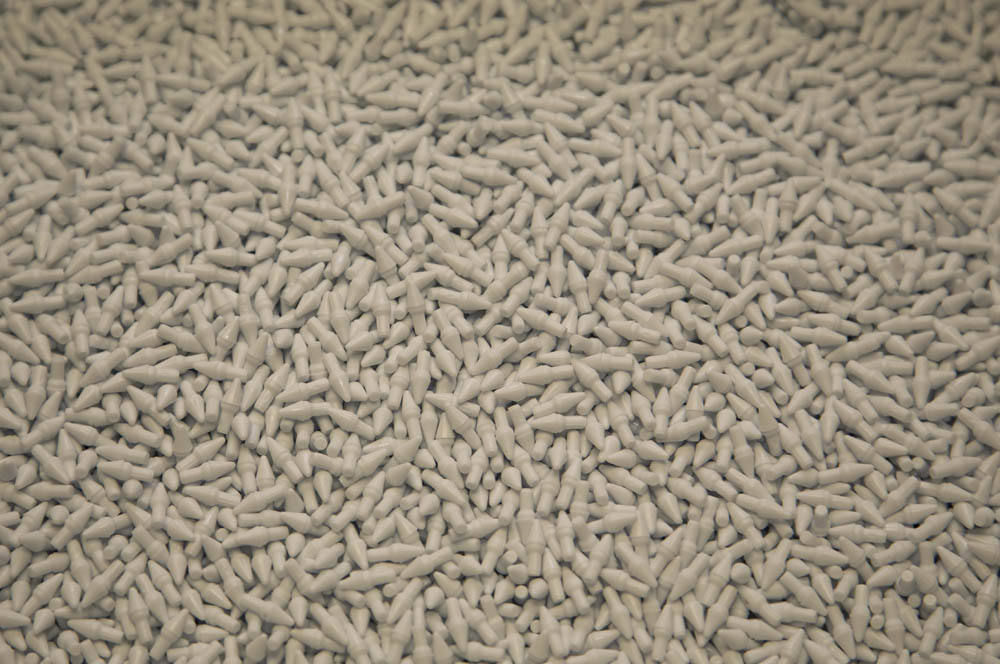

Read MoreKASO ENGINEERS TEAM UP WITH RTP COMPANY TO FIND NEW MATERIALS SOLUTION FOR WERNER PADDLES

KASO engineers were recently challenged with finding a new material solution for Werner Paddles—makers of some of the world’s finest kayak, canoe and stand-up paddles—ultimately finding their solution in a very unlikely place: carbon fiber reclaimed from manufacturing scrap from Boeing’s 787 Dreamliner airplane production. The search for a material that was both tough and…

Read MoreINJECTION MOLDED MEDICAL DEVICES LEAD GROWTH IN THE MEDICAL MARKET

Already a $56 billion industry in the United States, the Medical product market shows no signs of slowing in coming years, in particular due to the continued innovation in injection molded medical devices, according to a recent article published in PlasticsNews this month. While the medical market also includes unique challenges for manufacturers–strict FDA regulations, for one,…

Read MoreCOMBINED EFFORTS OF KASO AND RTP COMPANY PROVIDE AESTHETICS SOLUTION FOR WERNER PADDLES

KASO Plastics engineers and custom compounder RTP Company teamed up recently to assist Werner Paddles when the company began to experience aesthetic issues with its kayak paddle blades. After experimenting with more than a dozen different materials, KASO engineering staff found that it was a recycled aircraft grade carbon fiber from RTP Company that did the trick.…

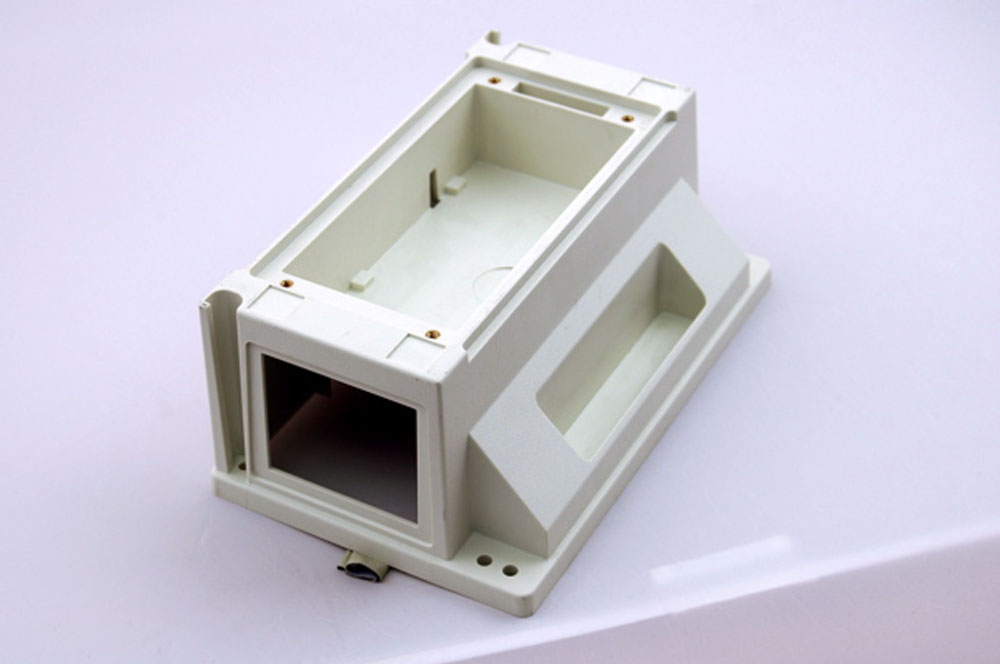

Read MoreMETAL TO PLASTIC PART CONVERSIONS – DISCOVER A LIGHTER WEIGHT SOLUTION TO METAL PARTS

Aware of basic benefits gained from metal to plastic conversion, OEMs have been converting heavier metal parts into lightweight plastics for years. But what these same manufacturers may not know is that, as technology improves and new materials continue to improve, the number of parts suitable for conversion continues to grow as well. Advantages to converting…

Read More

Molding services for Agricultural customers

Molding services for Agricultural customers