Uncategorized

Top Plastics Materials for Injection Molders

Injection molding produces a wide variety of products and components for applications throughout the world. While each individual application requires a customized product design based on specific details, part specifications and uses, there are several materials that are the most popular for use in injection molding processes. Understanding a little bit more about the top…

Read MoreHOW TO EMPOWER YOUR DESIGN TEAM TO CREATE BETTER PRODUCTS

THE RIGHT TEAM FOR THE JOB During the product design process, there are a number of factors to take into consideration in order to ensure a successful delivery to market. To ensure the best outcomes possible, it’s important that you gather the right team. But even the best team members won’t be able to reach…

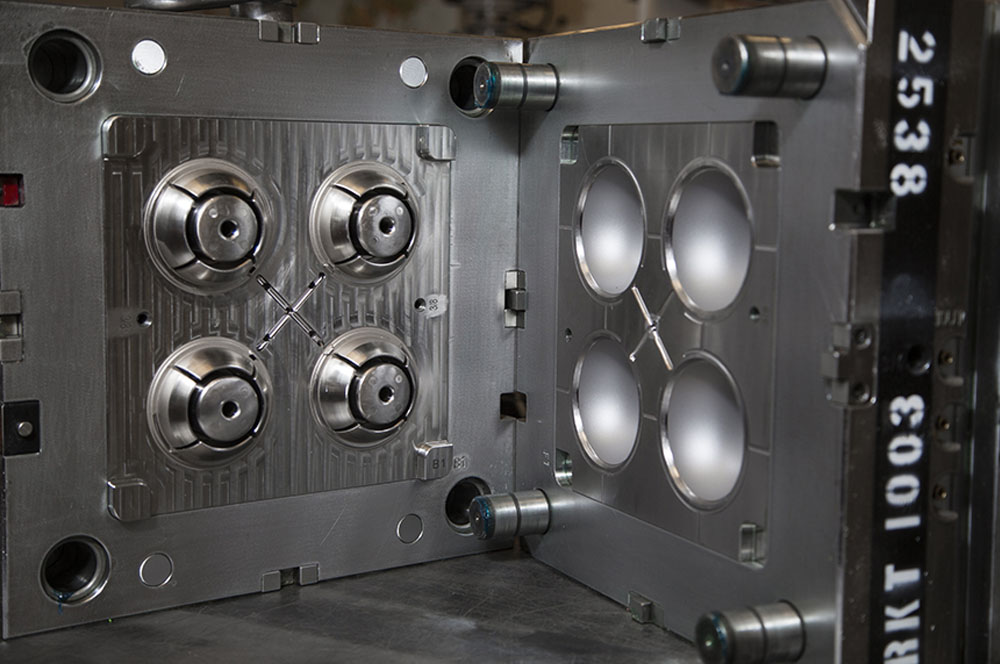

Read MoreWHAT YOU NEED TO KNOW ABOUT INJECTION MOLD MAINTENANCE

If you have a car, you already know the best way to prevent major issues is to invest in regular care and maintenance. This same principle holds true when it comes to your injection molds. These tools are not only expensive, but will also be used over and over again. Therefore, preventative maintenance on a…

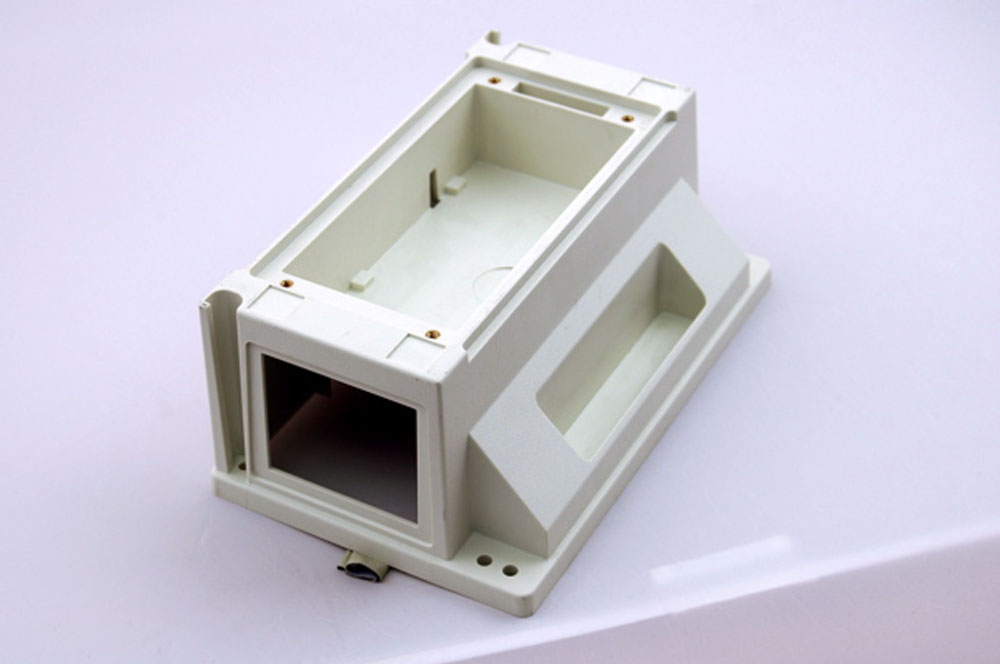

Read MoreAS TECHNOLOGY CONTINUES TO EVOLVE, DEMAND FOR EMI AND RFI SHIELDING GROWS

ELECTRONICS EVERYWHERE Over the last few decades, technological advancements have made an incredible impact on our society. From the electronic systems integrated into Aerospace equipment to the smart phone that you use every day, electronic and digital infrastructure is all around us. And even though all of this new technology has enhanced connectivity, promoted advancements…

Read MoreIN HONOR OF NATIONAL MANUFACTURING DAY: MANUFACTURING TRENDS TO GET EXCITED ABOUT

October 6th is National Manufacturing Day, a day set aside to celebrate modern manufacturing and inspire the next generation of workers to get excited about new opportunities and trends in manufacturing. Manufacturing is changing, and it’s important for us to help ‘set the record straight’ when it comes to some of the misperceptions people have…

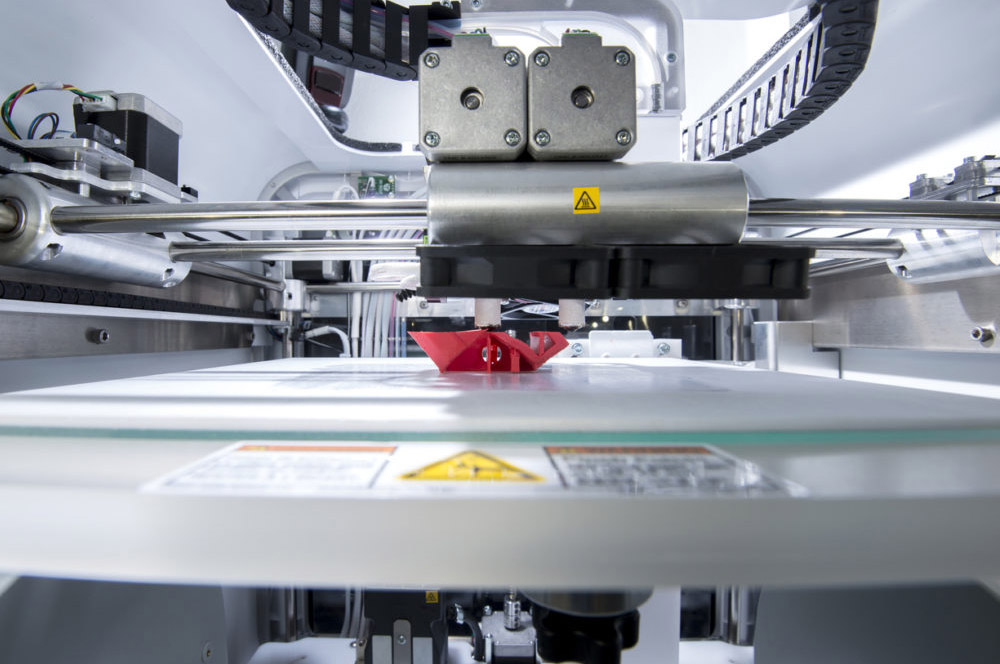

Read MoreENGINEERING AND RAPID PROTOTYPING SERVICES AT KASO – INVESTING IN YOUR SUCCESS

KASO ENGINEERING SERVICES Productivity and profitability are two key factors for contract manufacturing success, and there are many methods that can be implemented to improve both. Productive management of your time and resources will help increase your profits while reducing any potential loss via design or manufacturing inefficiencies. KASO Plastics offers an opportunity for our…

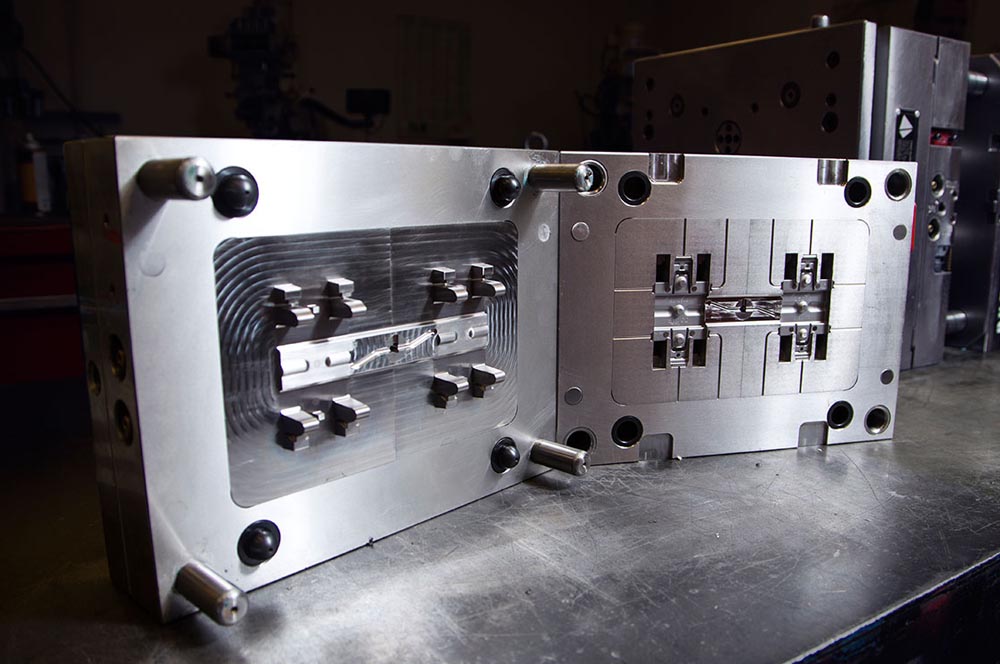

Read More3 REASONS WHY YOU MIGHT NOT NEED IN-HOUSE TOOLING AFTER ALL

Arguments abound touting the benefits of in-house mold tooling capabilities. But does the reality live up to the hype? The short answer: Not necessarily.. 1. THE TRICKLE DOWN EFFECT The longer answer is that, while many shops claim their in-house mold tooling can reduce your time to market, help you avoid downtime for repairs and…

Read MoreINJECTION MOLDED MEDICAL DEVICES LEAD GROWTH IN THE MEDICAL MARKET

Already a $56 billion industry in the United States, the Medical product market shows no signs of slowing in coming years, in particular due to the continued innovation in injection molded medical devices, according to a recent article published in PlasticsNews this month. While the medical market also includes unique challenges for manufacturers–strict FDA regulations, for one,…

Read MoreEXPERTS SHARE THEIR PREDICTIONS FOR THE MEDTECH INDUSTRY IN 2012

In a recent editorial (“Blue Skies or Clouds Ahead for Medtech Industry? Experts Make Their 2012 Predictions”), Medical Device and Diagnostic Industry web editor Heather Thompson surveyed several leading experts in the Medical Device industry to get their opinion on the future of the medical device industry in 2012. Among the predictions? Greater opportunities to…

Read More

Molding services for Agricultural customers

Molding services for Agricultural customers