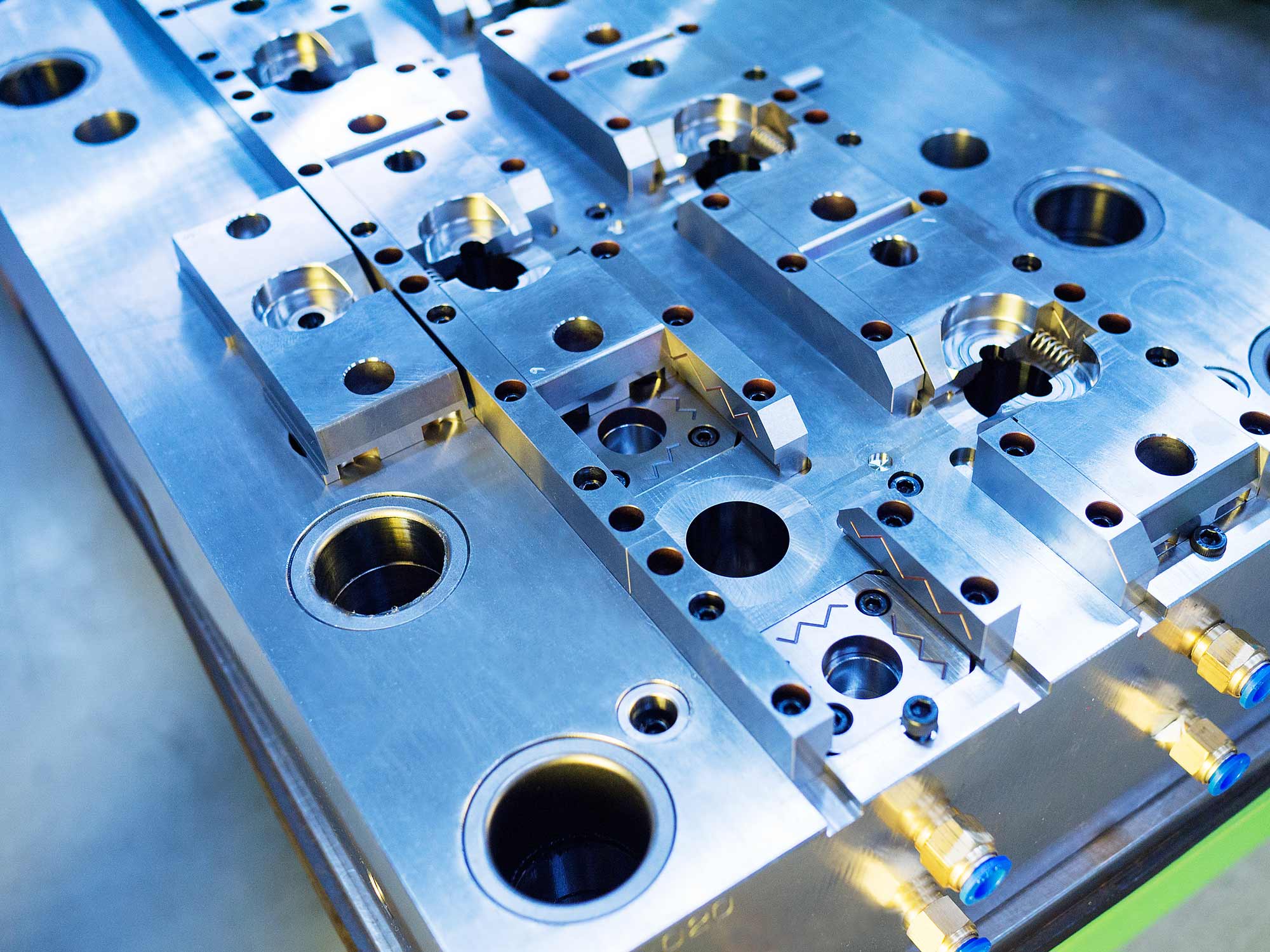

METAL TO PLASTIC CONVERSION PROJECTS

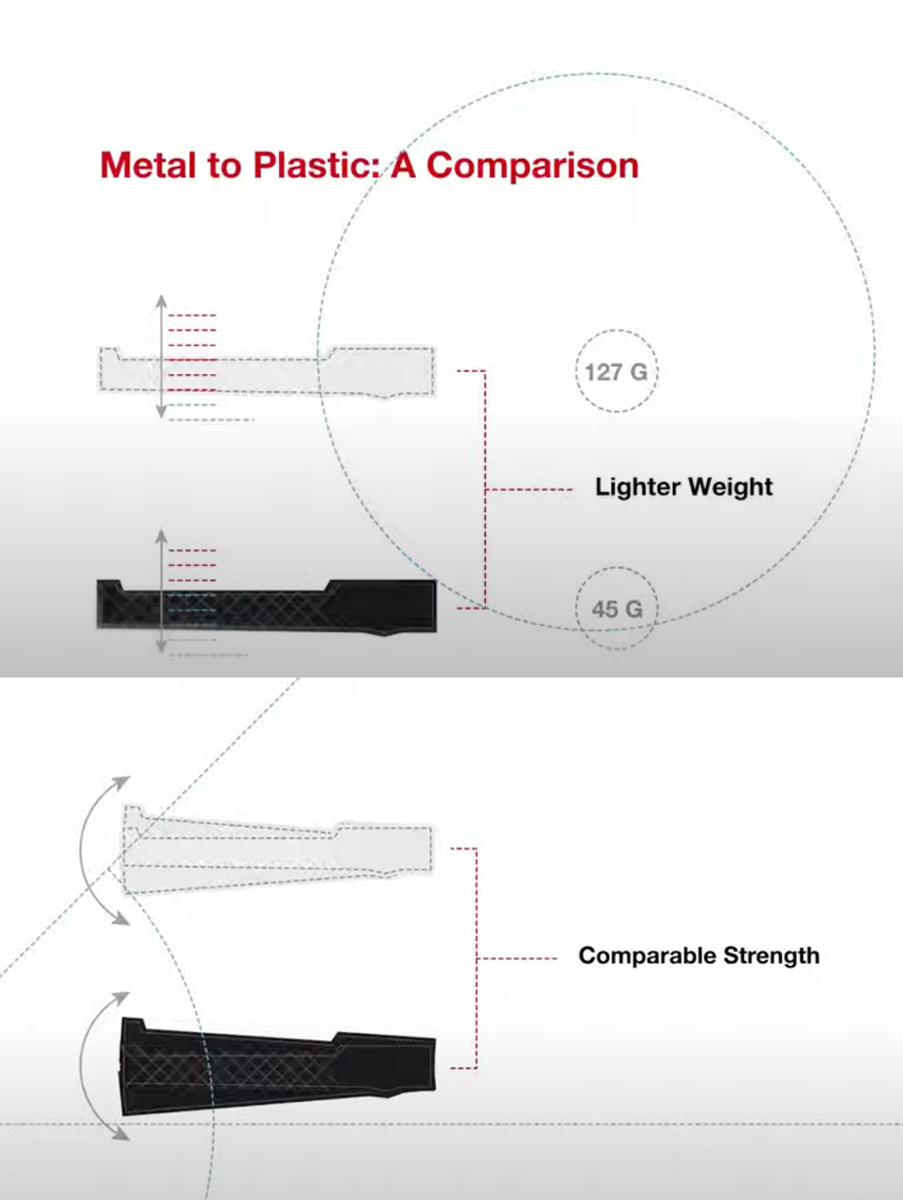

Metal to Plastic Conversion projects are common at KASO. Our engineers can help you take those expensive, heavy metal parts and convert them to lightweight, lower cost plastic parts suitable for plastic injection molding, all without compromising structural integrity. In many cases this offers better performance and greater design freedom in addition to creating real and meaningful savings during manufacturing.

KASO'S EXPERIENCED ENGINEERING TEAM

MATERIALS SELECTION EXPERTISE

KASO’s engineering team is here to assist your team in evaluating the feasibility of converting from metal to plastic and assisting you in selecting the right material to meet your requirements and your budget. Our knowledge of injection molded plastics includes analysis and deep material expertise. Let us help you comply with international regulations, lower total costs and/or reduce product weight while delivering improved design, flexibility, and performance with the use of injection molded plastic.

BENEFITS OF METAL TO

PLASTIC CONVERSION

- Increased Strength and durability

- Lighter weight parts

- Improved quality and consistency

- Reduced labor and time for manufacturing

- Better appearance

- Corrosion resistant parts

- Temperature resistant

- Lower manufacturing costs

- Create more complex shapes

- Ability to combine materials

METAL TO PLASTIC

APPLICATIONS AND USES

- Industrial parts

- Automotive weight reduction

- Construction equipment

- Consumer products

- Handheld devices

- Agriculture equipment

- Appliances

- Off road vehicles

- Electronic housing components

- EMI/RFI shields

- Instrument housing

With metal to plastic conversion, you get greater materials selection options, greater flexibility in design and geometry, plus lower shipping costs allowing for greater savings.

Learn more about Metal to Plastic Part Conversion for Automotive Lightweighting.

Visit us on social media

Molding services for Agricultural customers

Molding services for Agricultural customers