KASO’S AUTOMOTIVE INJECTION MOLDING ADVANTAGE

Metal to Plastic Conversion projects are common at KASO. Our engineers can help you take those expensive, heavy metal parts and convert them to lightweight, lower cost plastic parts suitable for plastic injection molding, all without compromising structural integrity. In many cases this offers better performance and greater design freedom in addition to creating real and meaningful savings during manufacturing.

CUSTOM TRUCKING & HEAVY EQUIPMENT PRODUCTS

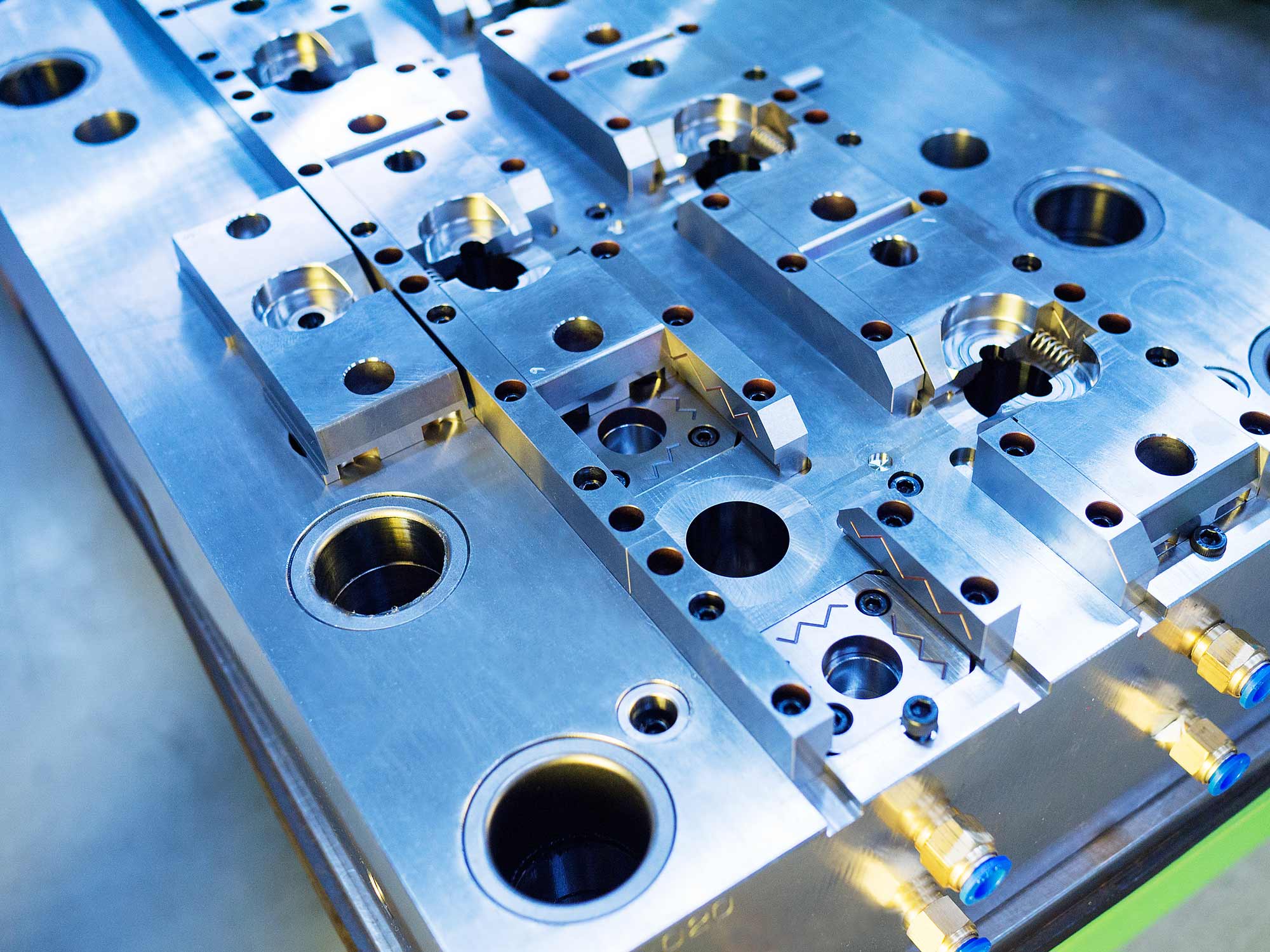

KASO’s range of plastic injection molding capabilities are ideal for custom automotive applications requiring lighter weight, lower cost plastic parts without compromising structural integrity. KASO’s engineering services are also located at our injection molding facility in Vancouver, Washington. KASO’s custom automotive capabilities include materials selection to help you evaluate a variety of engineering grade resins.

QUALITY MANUFACTURING

Automotive and industrial automotive parts requiring close-tolerance specifications with superior quality and aesthetics are no problem for our full-service facility. KASO can also assist with subassembly and electro-mechanical integration.

Visit us on social media

Molding services for Agricultural customers

Molding services for Agricultural customers