ENGINEERING SUPPORT YOU CAN COUNT ON

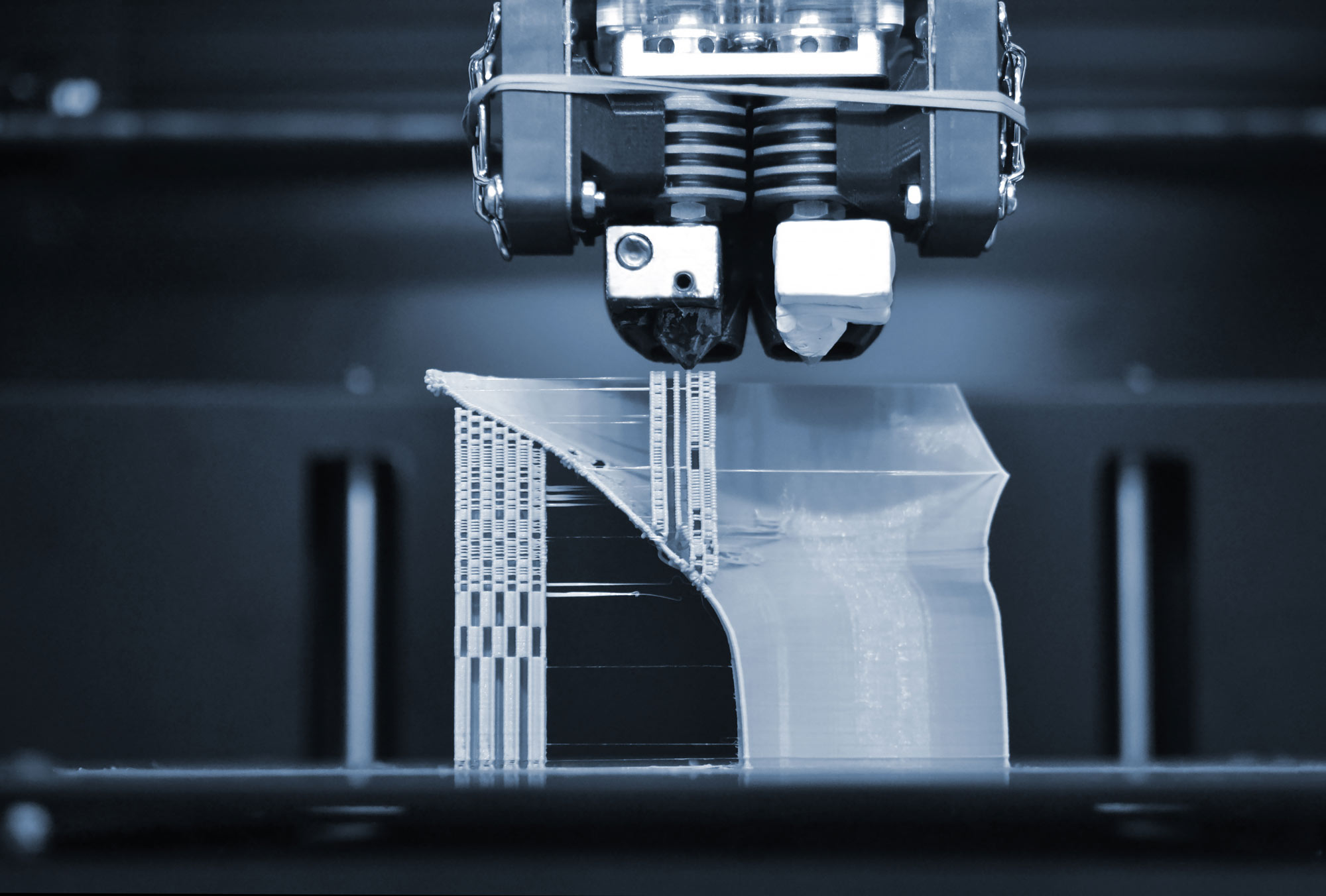

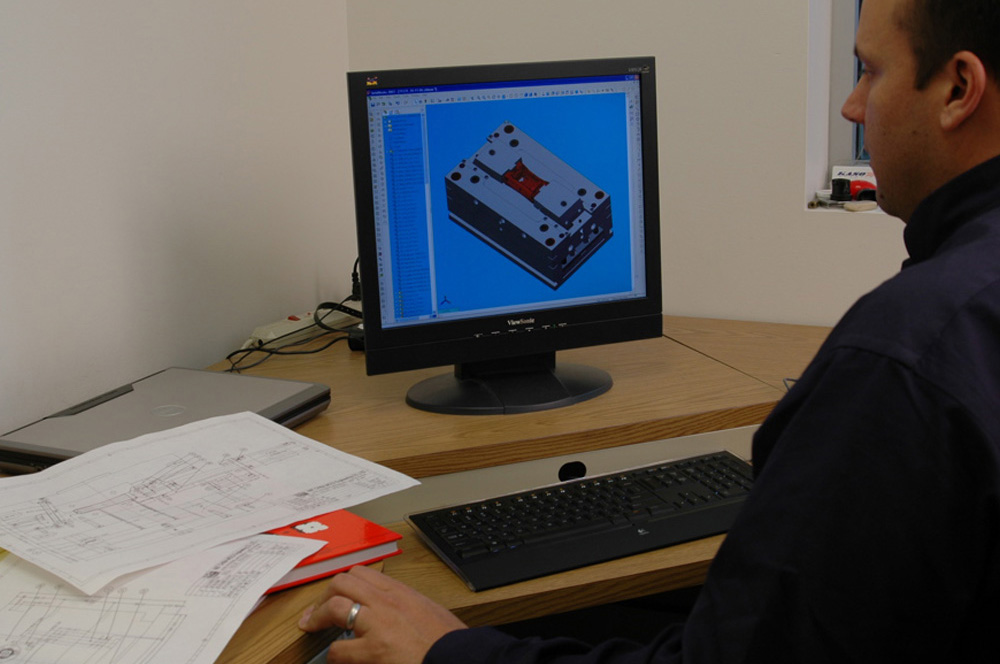

KASO’s expert engineering team has the tools you need to prepare products for successful manufacturing. From our initial contact, KASO’s product design and engineering assistance has you covered. Take advantage of our experience with plastic part design and the Design for Manufacturing (DFM) review to injection mold design, mold flow analysis, materials selection, prototyping, and even 3D printing support.

PLASTIC PART DESIGN

Early involvement with your manufacturing partner can reap huge benefits, helping you bring products to market quickly with the highest quality and lowest cost. By getting KASO involved earlier in the product development process, you’ll have the opportunity to communicate crucial information about your project’s requirements and maximize the benefit of design optimization.

MATERIALS SELECTION

Proper specification of materials is one of the most important elements of a well-engineered product. The materials chosen for each part will play a major role in the ultimate success of injection molded parts and the overall project.

We invite you to leverage the knowledge and experience of KASO’s team of engineers to ensure you have the proper materials specified for each application. Our team has expert knowledge of a wide range of plastic materials and can ensure your products are engineered with a carefully balanced approach that considers both material characteristics and costs.

Proper materials selection includes careful analysis to understand your products, their applications, and your cost requirements. Choosing the right materials can provide:

- Longer product life span

- More attractive products

- Improved tensile strength as required for individual product designs

- Greater environmental and temperature resistance

KASO'S EARLY SUPPLIER INVOLVEMENT PROCESS

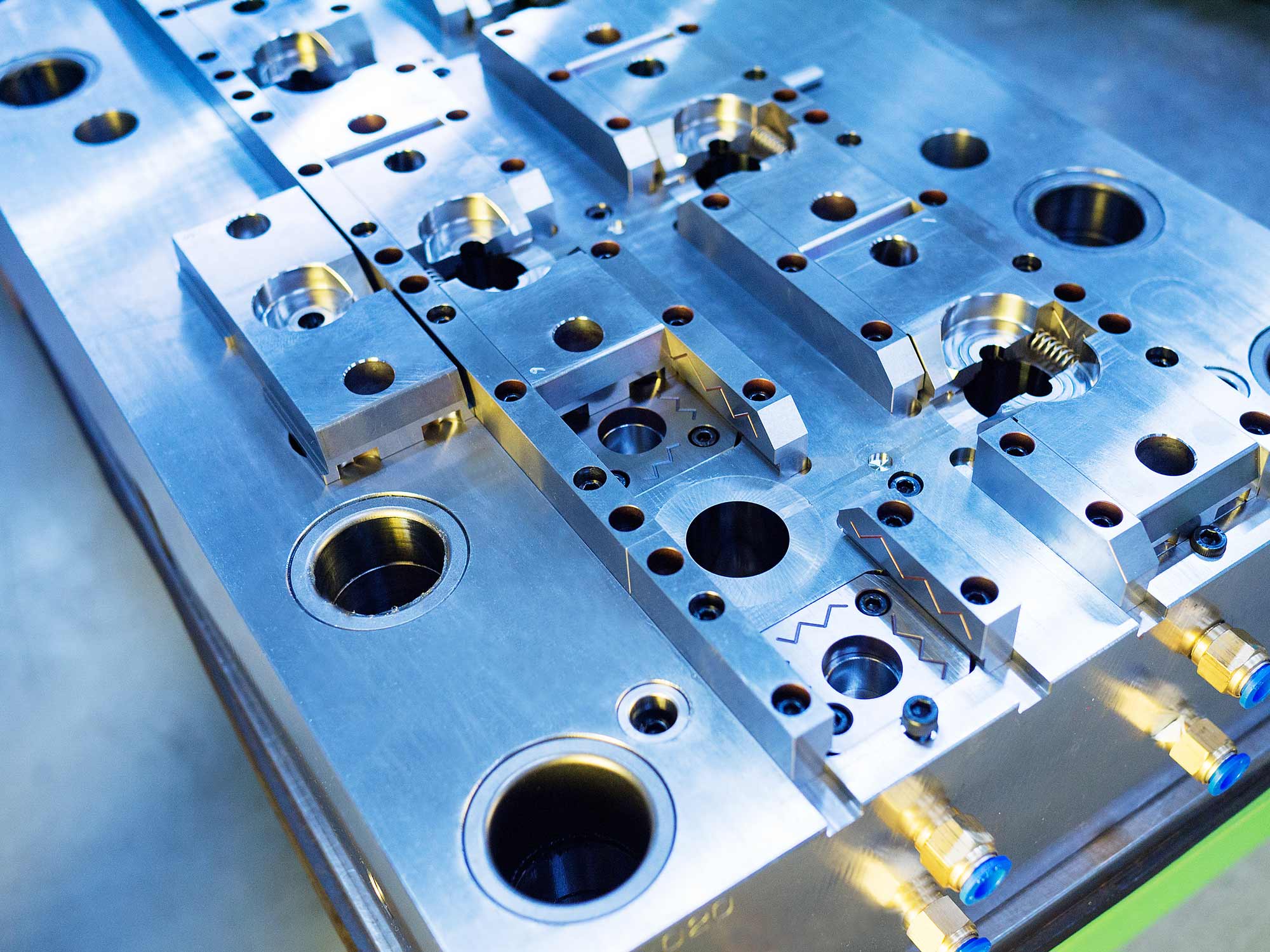

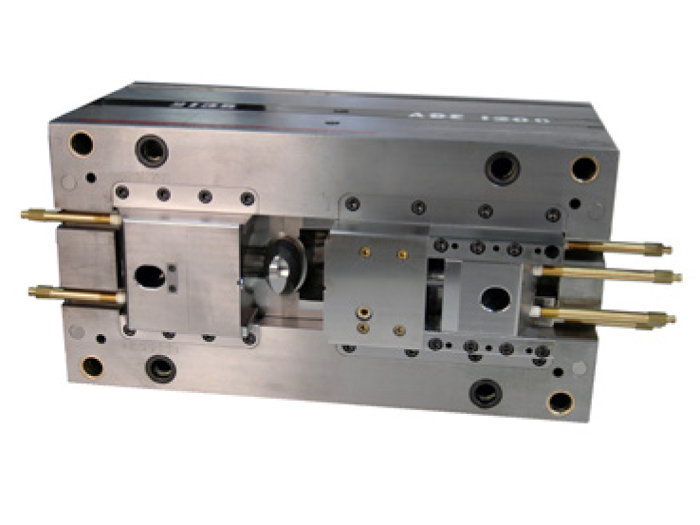

THE DESIGN FOR MANUFACTURING REVIEW

The Design for Manufacture Review gives KASO engineers the chance to understand your products requirements and allow us to guide changes that will result in reduced tooling costs, more robust tooling that will have longer life, and the most optimal and repeatable part quality. KASO’s seasoned engineering team can help optimize each element of the design and reduce your risk of developing products that are too complex or expensive to produce.

Learn more about the benefits of Design for Manufacturing.

OPTIMIZATION FOR MANUFACTURING

Optimization for Manufacturing involves the strategic application of our wide range of tools to maximize the efficiency, productivity and profitability of your product.

We consider the full life-cycle your manufactured products demand, from early stages of forecasting, through planning, scheduling, dispatch, execution and post-analysis.

Visit us on social media

Molding services for Agricultural customers

Molding services for Agricultural customers