MATERIAL SELECTION AT KASO PLASTICS

Choosing the correct materials for your injection molded products shouldn’t have to be a tough task. But with literally thousands of possibilities to choose from, it can be challenging to know just where to start when it comes to making the right choice for your products.

Popular Injection molding materials

These are just a few of the materials most frequently found in injection molded products:

ABS Plastic

ABS is one of the most commonly used injection molding materials, due to its relatively low cost and structural strength.

Polycarbonate

Polycarbonate is another frequently used material, most notably for applications that require a high level of transparency or that will be subjected to high heat.

Ultem

Ultem is a high performance plastic that is often used in medical, electronic, and aerospace applications due to its prolonged heat resistance and outstanding strength properties.

Polypropylene

Polypropylene is another popular material that is used in a wide variety of applications. Its relatively high chemical resistance makes it a good option for containers and packaging.

Acetal

Acetal is another high performance polymer, one that is often used for parts that would otherwise be made from metal materials.

Nylon

Nylon can be used for many things, including rope! It is also a good choice for components that require extremely high strength.

Polyethylene

Aside from ABS, Polyethylene is perhaps the most widely used polymer on our list. That’s because it comes in many varieties, each well suited to particular applications.

When it’s time to make your important material selections, turn to the experts at KASO Plastics. Our materials experts have years of experience working with a huge range of plastic resins and can help you narrow your options to ensure you get the materials that are best suited to your application.

WHY MATERIAL SELECTION MATTERS

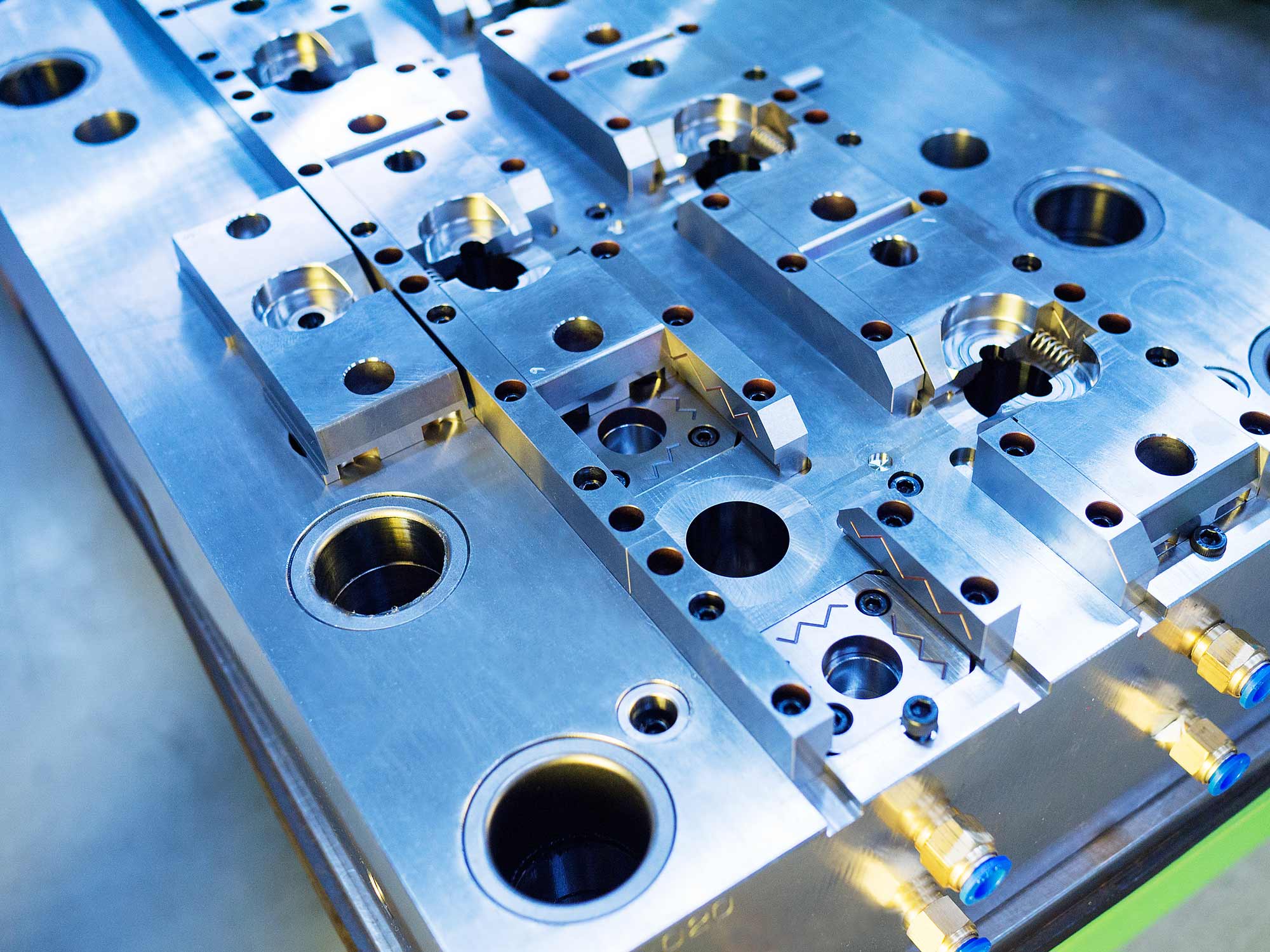

Proper material selection for injection molding will protect you from costly tooling adjustments once production has begun. Because injection molds are built for a specific shrinkage, making the right material selection is a crucial component of any successful injection molding project. There are several factors to consider when it comes to selecting the proper materials.

What is the part’s application? Will it be load bearing in a high-heat environment, like an engine compartment? What will you require aesthetically for its finish, texture, or color? Will your product require overmolding? Our experts will work with you to understand all of your requirements, from bonding to rigidity and heat deflection. We will also consider any post-injection molding processes the part will undergo, like pad printing or the addition of an adhesive logo.

CONSIDERATIONS FOR HIGH VOLUME PLASTIC PARTS

For higher volume projects, you’ll need to consider whether price or performance is your top priority. For price-sensitive parts or components, a commodity plastic can be a great choice to help you save. KASO maintains excellent vendor relationships with all of our resin suppliers, so you know you’ll always get the best possible price available. For highly engineered components, KASO can help you choose between a variety of unique materials to help your product stand out.

Whatever products you’re shopping for, KASO has the material expertise that will help you make the right choice at the best price.

Learn more about the important factors you’ll want to consider as you begin the material selection process.

Visit us on social media

Molding services for Agricultural customers

Molding services for Agricultural customers