RAPID PROTOTYPING AND 3D PRINTING AT KASO PLASTICS

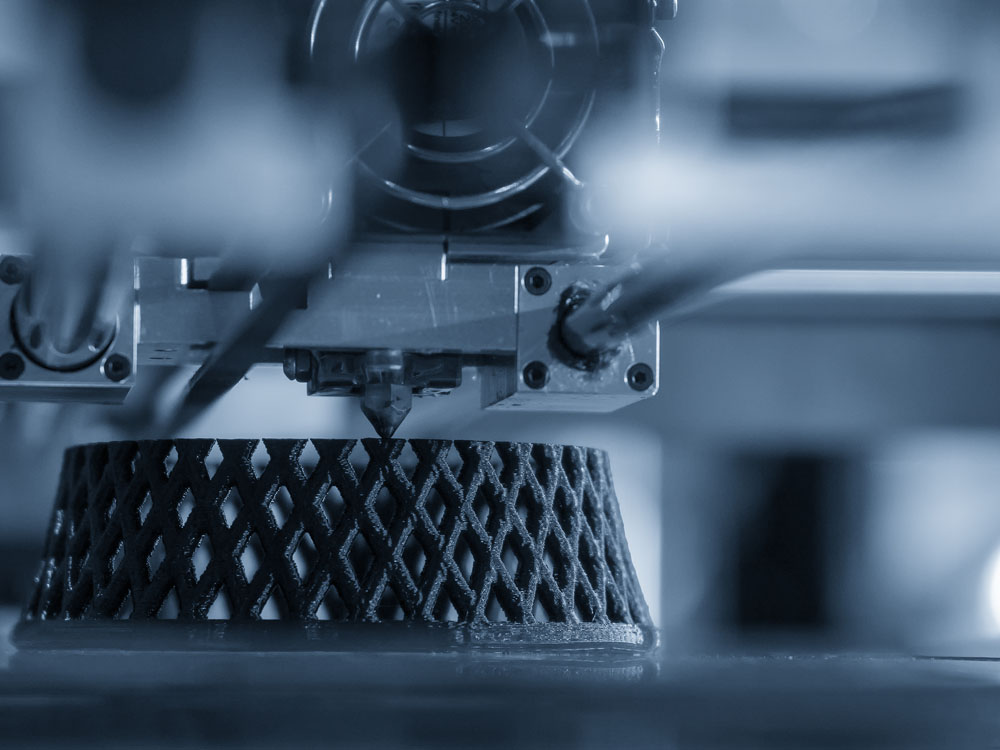

Rapid prototyping plays a major role in successful product development. Utilizing 3D prototypes prior to plastic injection molding, KASO’s expert engineers will help you identify any errors or flaws in part geometry long before final manufacturing is underway. You’ll save considerable time and money throughout your product’s development.

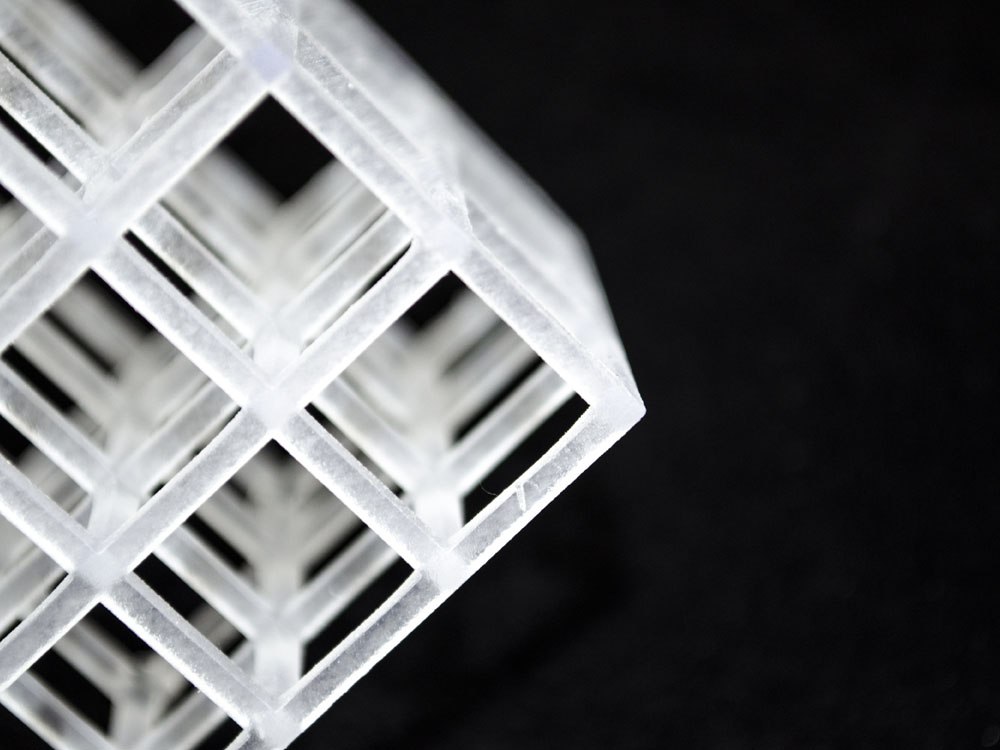

At KASO, we use Fused Deposition Modeling (FDM) to create 3D printed parts. Our prototype parts boast up to 80% of the strength of parts produced using traditional plastic injection molding processes. Our FDM printed parts will provide a very accurate representation of the strength one can expect of the final molded part.

KASO'S 3-D PRINTING SERVICES INCLUDE:

- Engineering and conceptual models

- Finished parts

- Master patterns

- Special fixturing and tooling

All you need to get started is a CAD file + a brief description of your application. We can then provide you with a detailed estimate for KASO’s rapid prototyping services.

BENEFITS OF FDM 3D PRINTING

KASO’s 3D printing utilizes FDM grade ABS thermoplastic materials to create high-quality parts that are extremely reliable and often strong enough to be used in real-world applications. Our fast and reliable 3D printing is a great option for both rapid prototyping and short-run production manufacturing.

This adds flexibility to your production, reduces your time to market, and makes it easier than ever to test products before full production begins.

Visit us on social media

Molding services for Agricultural customers

Molding services for Agricultural customers