THE STRUCTURAL FOAM MOLDING PROCESS

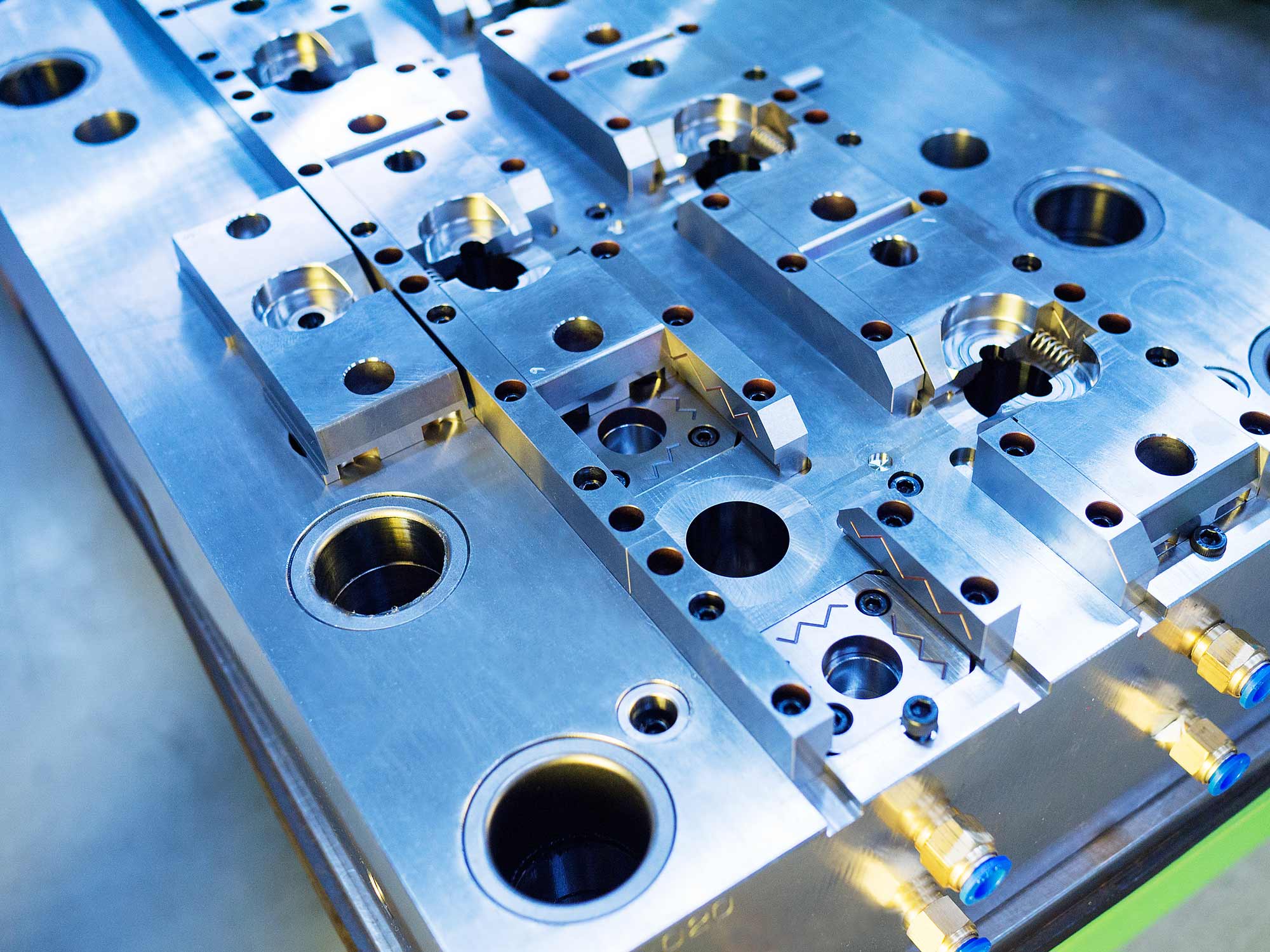

Structural foam molding is a plastic injection molding technique we use at KASO that can be a great option for larger projects. It is most beneficial when a thick structural part is desired as in chassis’ and frames. It is also an excellent choice for external housings and bases where a high level of rigidity is crucial.

Structural foam molding is often the ideal solution for large parts, reducing tonnage and creating a more stable part. Plastic parts manufactured using this technique have enhanced strength and strength to weight ratios and can reduce mold weight up to 20%. Structural foam molding also offers low-cost tooling and a wide range of design flexibility.

The structural foam molded part will always be lighter than its standard injection molded counterpart. The thicker the part, the more weight is reduced.

WHEN SHOULD YOU CHOOSE STRUCTURAL FOAM MOLDING

This technique is commonly used for products such as door handles and other large “solid” pieces. Our team can help answer your questions about structural foam injection molding.

BUILDING THE RIGHT PART

KASO’s team will work closely with you to determine the correct production techniques to help you meet your business goals and create the best plastic products and parts. Our attention to detail and customer service is why we are the top choice for structural foam molding in the Pacific Northwest.

Visit us on social media

Molding services for Agricultural customers

Molding services for Agricultural customers