SUPERIOR PLASTIC PARTS

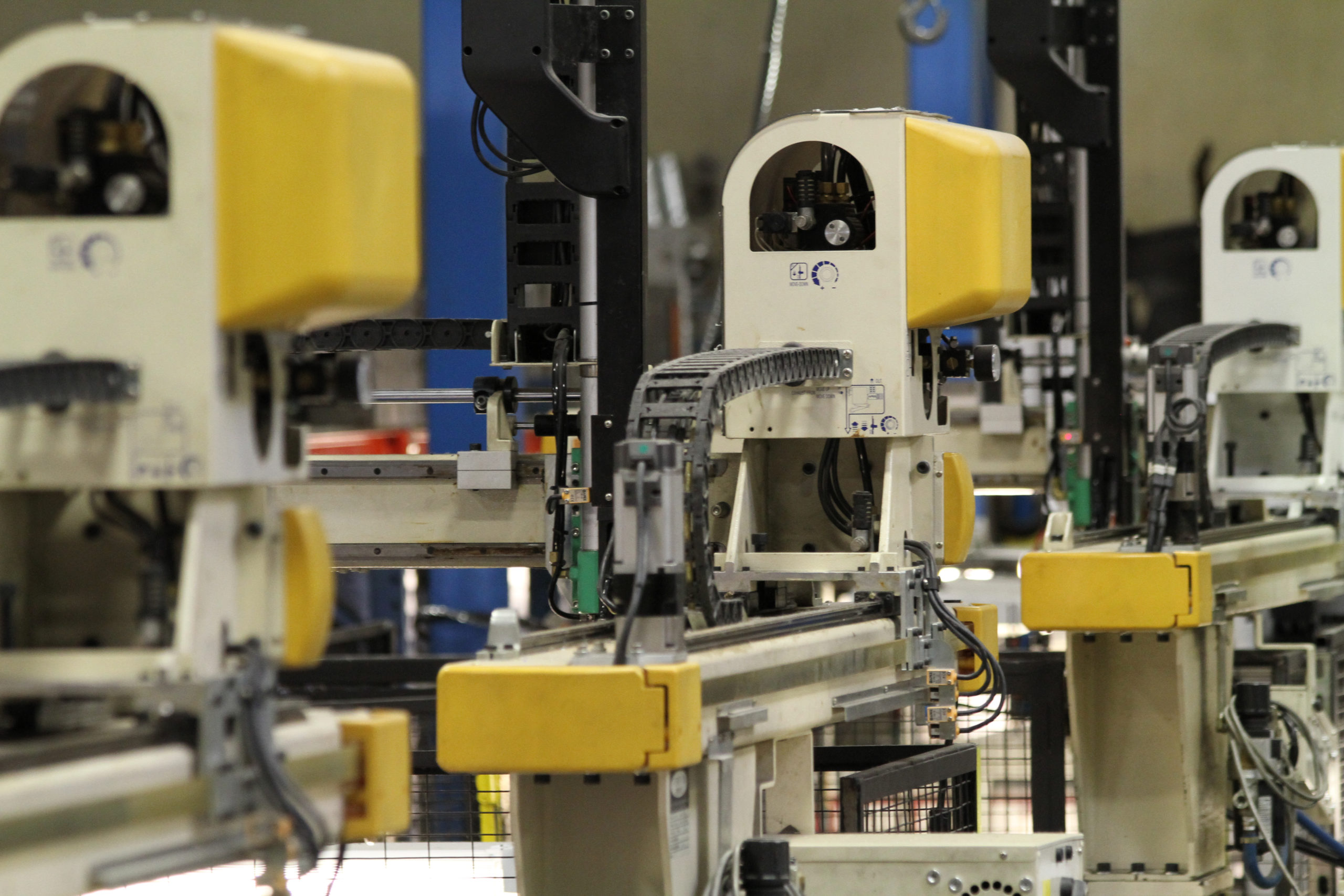

Founded in 1962, KASO Plastics is a full-service injection molder of high-quality, close-tolerance plastic parts.

KASO’s manufacturing facility in Vancouver, Washington boasts 65,000 square feet of cutting-edge technology including 55 to 610-ton all-electric injection molding machines fully equipped for long and short run production. We utilize the most modern equipment and skilled staff to provide high-quality parts at competitive prices.

QUALITY YOU CAN TRUST

You will find quality throughout every step of KASO’s injection molding services. Visual checks are integrated into our manufacturing processes as well as automated tolerance verification.

PLASTIC INJECTION MOLDING SERVICES

A versatile technique, gas assist injection molding creates resilient products and reduces part weight by utilizing pressurized nitrogen to strategically core out thick cross sections.

Insert molding and overmolding are two techniques used to combine different materials. Insert molding includes injecting plastic into the mold cavity prior to injection molding; overmolding is used to mold an additional plastic layer around a part that’s already been molded.

A technique that reduces tonnage to create a more stable part. The thicker the part, the more its weight is reduced. Structural foam molding also offers low-cost tooling and a wide range of design flexibility.

ADDITIONAL Injection Molding and

Support Services Include:

-

Pad printing

-

In-mold labeling

-

Ultrasonic welding

-

Assembly

-

Supply chain coordination

-

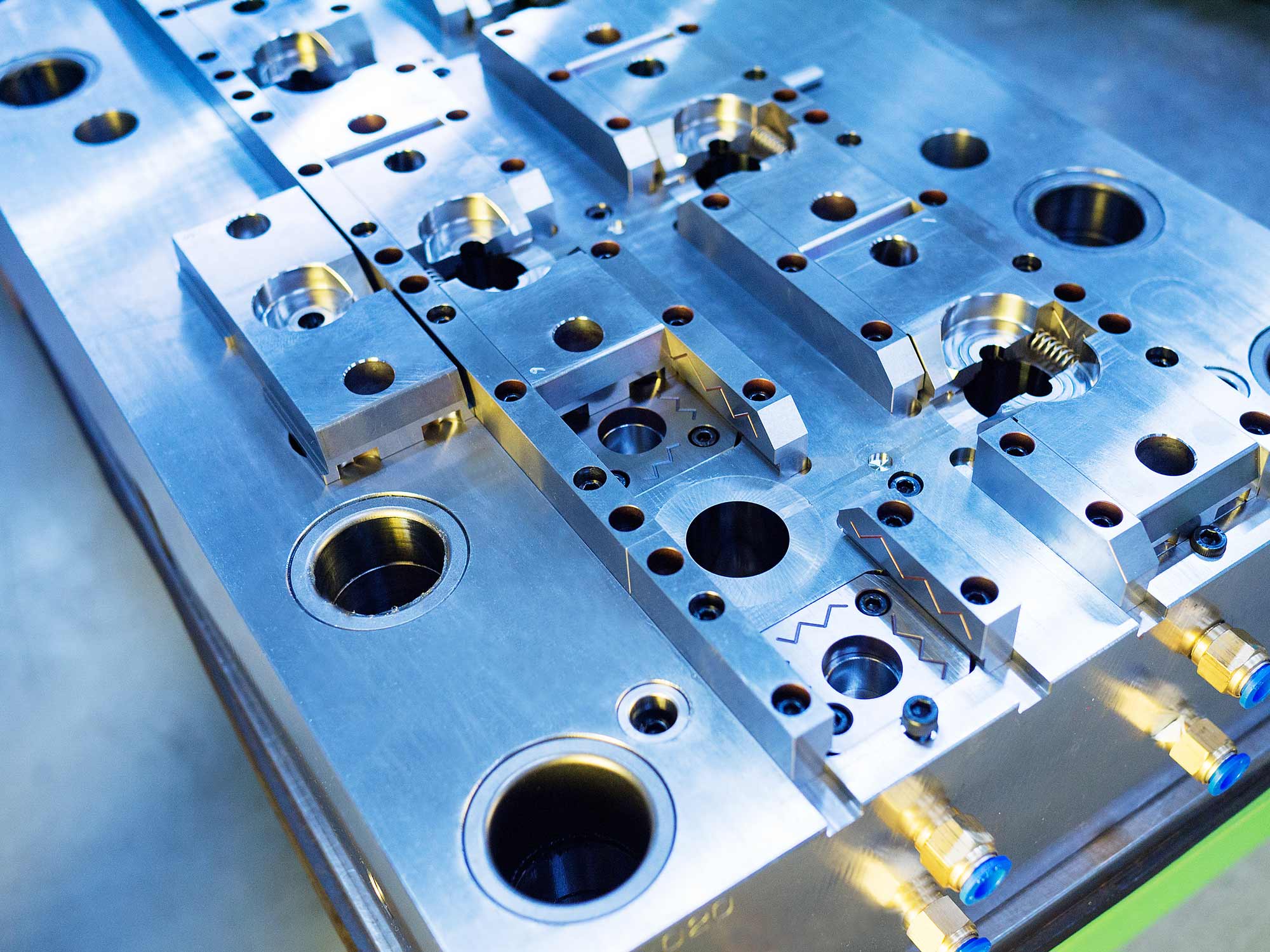

In-house tooling support

-

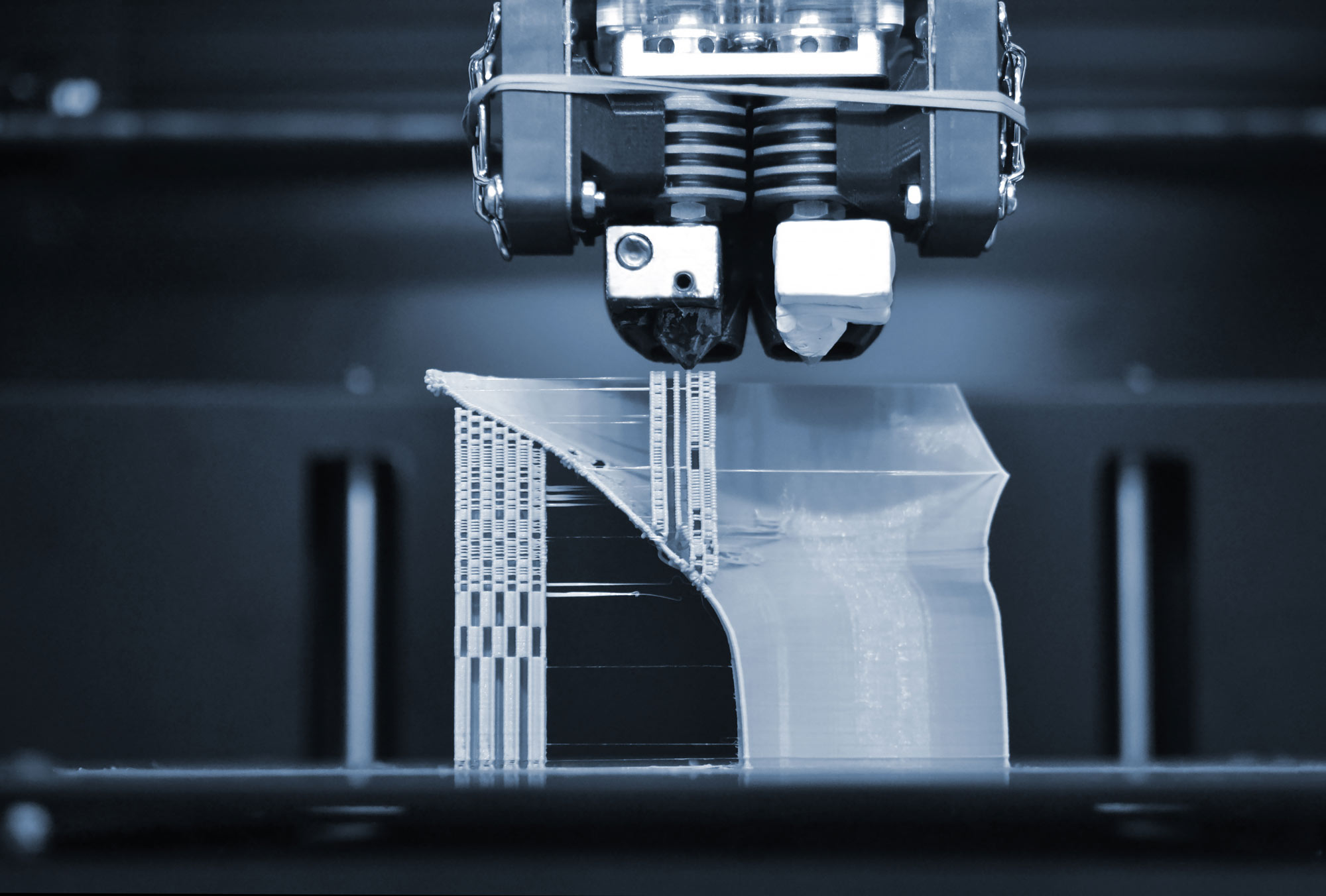

On-site 3D printing and rapid prototyping

QUALITY YOU CAN TRUST

We know your plastic injection molds are one of the most important investments you’ll make as you prepare your products for market. At KASO your molds receive full mold maintenance between every production run whether it’s cycle one or 200,000. Maintenance includes stripping, cleaning, and preventative maintenance, plus a full injection mold inspection to find any areas where normal wear and tear may have created stress areas. In addition to maintaining your investment we offer repair and modification services as well.

THINKING ABOUT CHANGING INJECTION MOLDERS?

There are many reasons companies choose to change manufacturers. We’re here to ensure the process is pain-free. From helping you evolve already existing designs to improving part quality and consistency, KASO can help you make the changes you need while helping you minimize the effects on your business.

Visit us on social media

Molding services for Agricultural customers

Molding services for Agricultural customers