MOLD FLOW ANALYSIS AT KASO

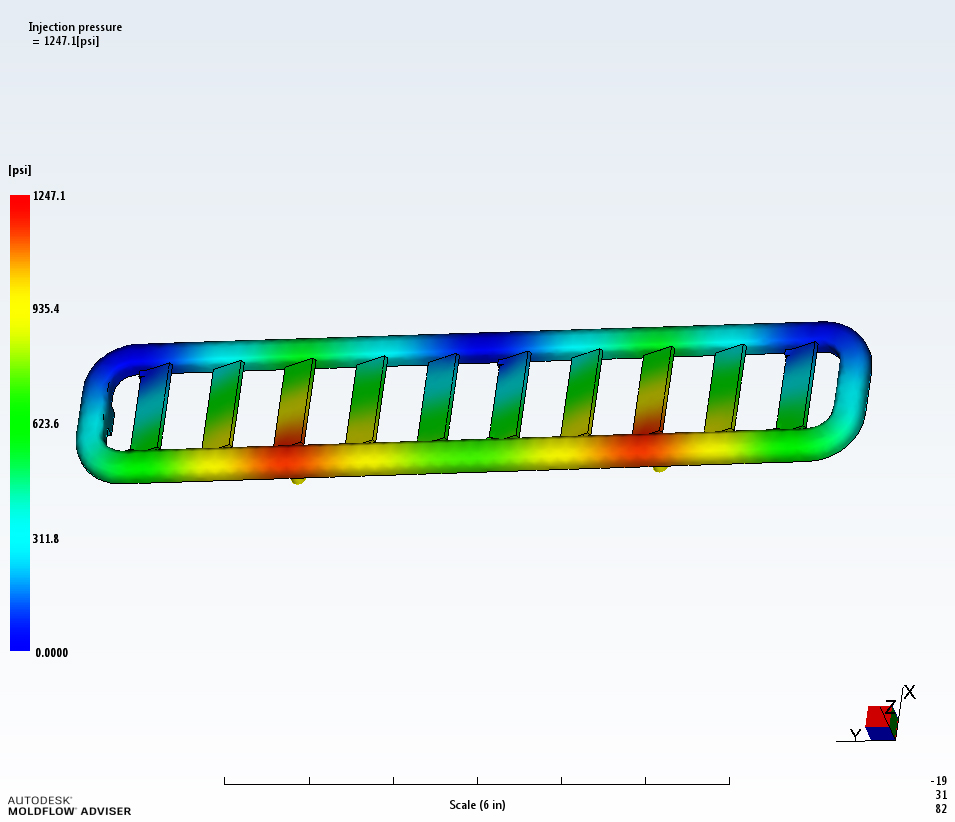

Mold flow is an analysis tool specifically designed for the injection molding industry. It is the single best tool our industry has to accurately predict how a part will mold.

KASO utilizes mold flow analysis as a tool to ensure an optimal molding process for the final product. Moldflow allows our engineers to determine the best approach to tool construction by identifying the best gate location and fill characteristics. Use of mold flow along with our decades of experience will ensure parts with the best possible dimensional stability, strength, and greatest overall part cosmetics.

As good as mold flow is at predicting how a part will mold it is not enough by itself to ensure the best molding process is achieved nor is it a replacement for actual experience. KASO uses mold flow analysis along with our decades of molding experience together to determine the most effective part and mold design which guarantees a truly optimal process.

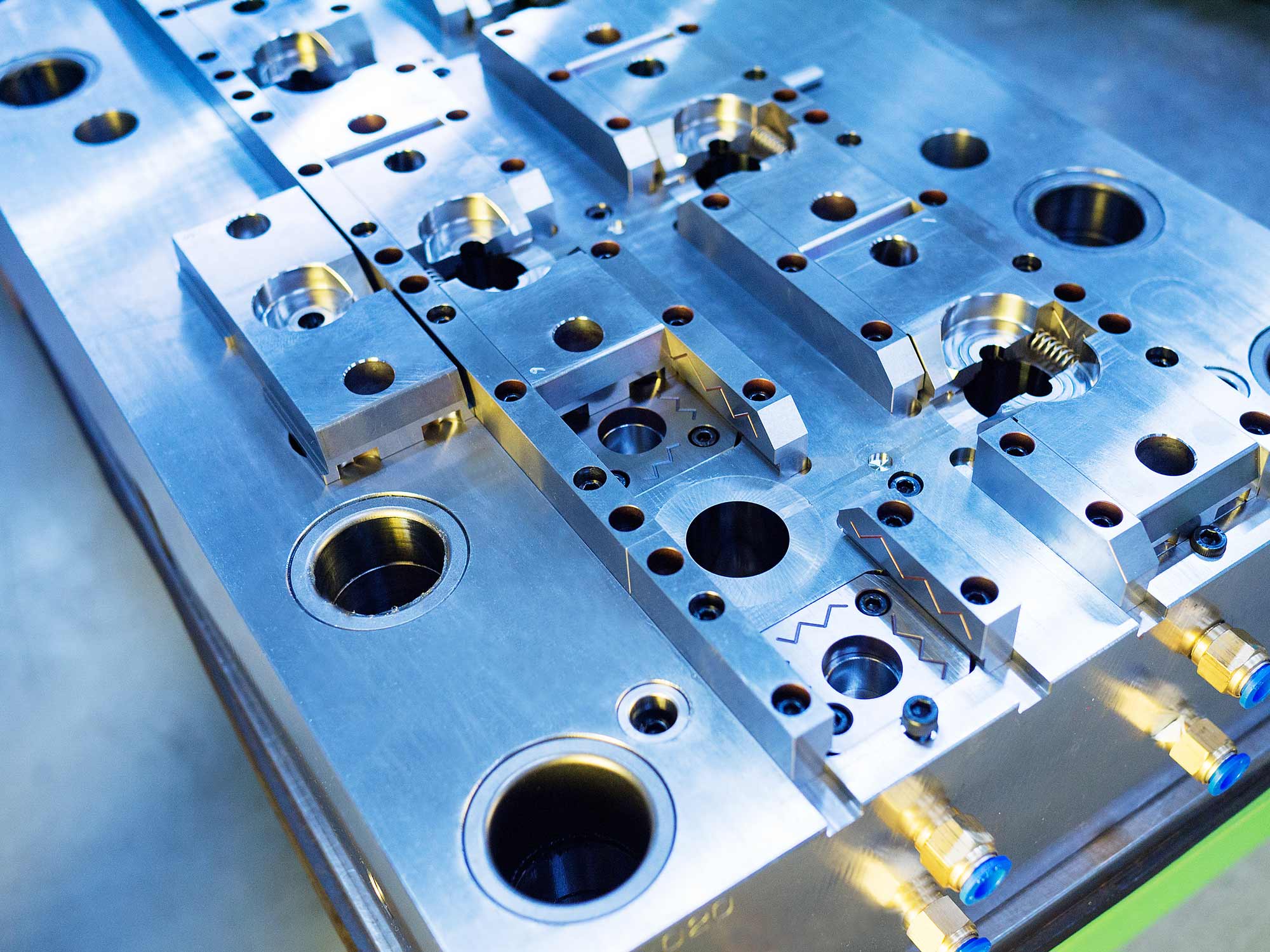

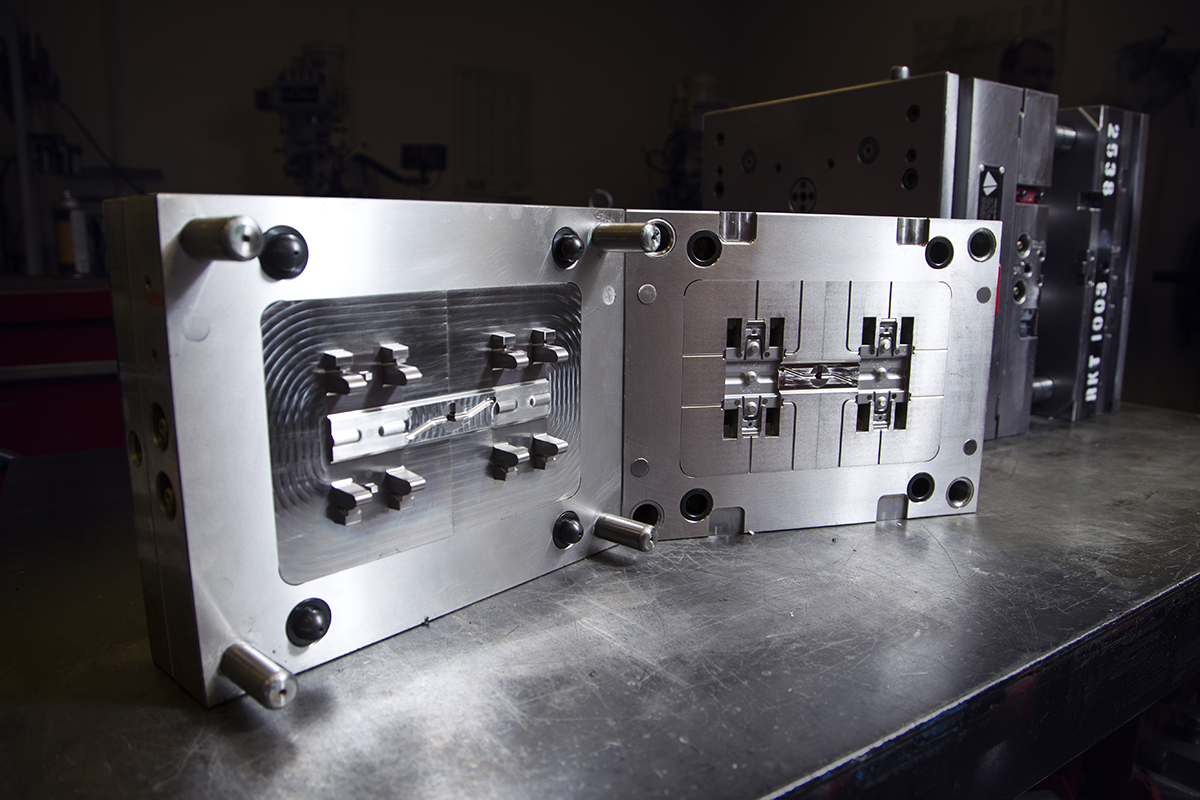

INJECTION MOLD DESIGN AND CONSTRUCTION

The type of mold construction we select is developed to meet your requirements concerning cost, part geometry, plastic material, and number of cycles. We follow guidelines developed by the Society of Plastics Industry, Moldmakers Division. We also have proven tooling design experience and over 30 approved domestic and off-shore tooling suppliers, so we can connect you to the moldmaker that will provide you with your specified requirements at the best value.

Did You Know?

KASO’s broad range of engineering capabilities are provided to KASO customers at no additional cost. Engineering consultation and support is included for every one of our injection mold projects, because we want you to experience a seamless production experience from initial concept to final production.

Visit us on social media

Molding services for Agricultural customers

Molding services for Agricultural customers