Posts Tagged ‘injection mold tooling’

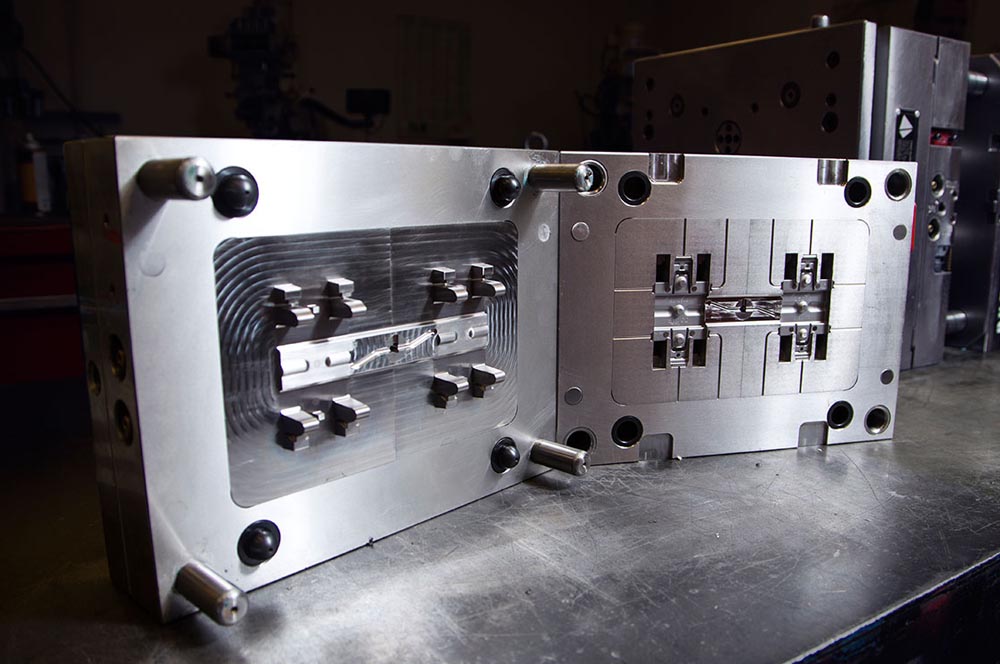

WHY ARE INJECTION MOLDS SO EXPENSIVE?

First-time product designers, we understand that the first look you get at how much your new product’s injection mold is going to cost can be… impactful. After all, the injection mold is the most expensive element of any new product launch. But why? Why are injection molds so dang expensive? INJECTION MOLD DESIGN AND TOOLING…

Read More3D PRINTED INJECTION MOLDS: A NEW WAY TO TEST PRODUCT DESIGNS

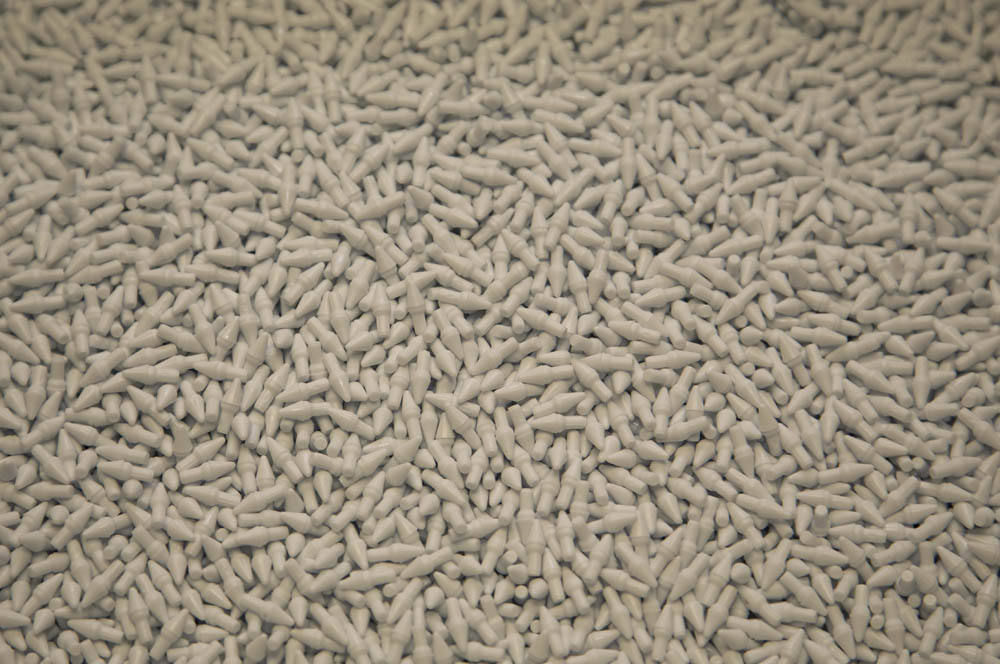

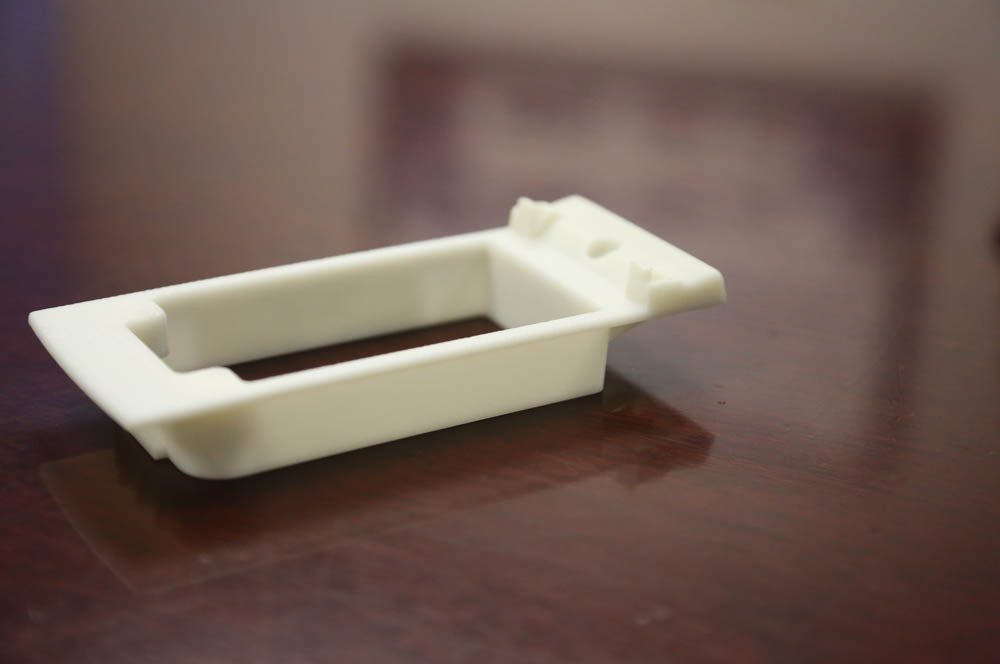

3D PRINTED PROTOTYPES 3D printing has long been used to create prototypes that can test out product designs to ensure the fit and function of new parts, but recently it’s been gaining steam as an effective tool for creating injection molds as well. 3D PRINTED INJECTION MOLDS What is there to be gained by using…

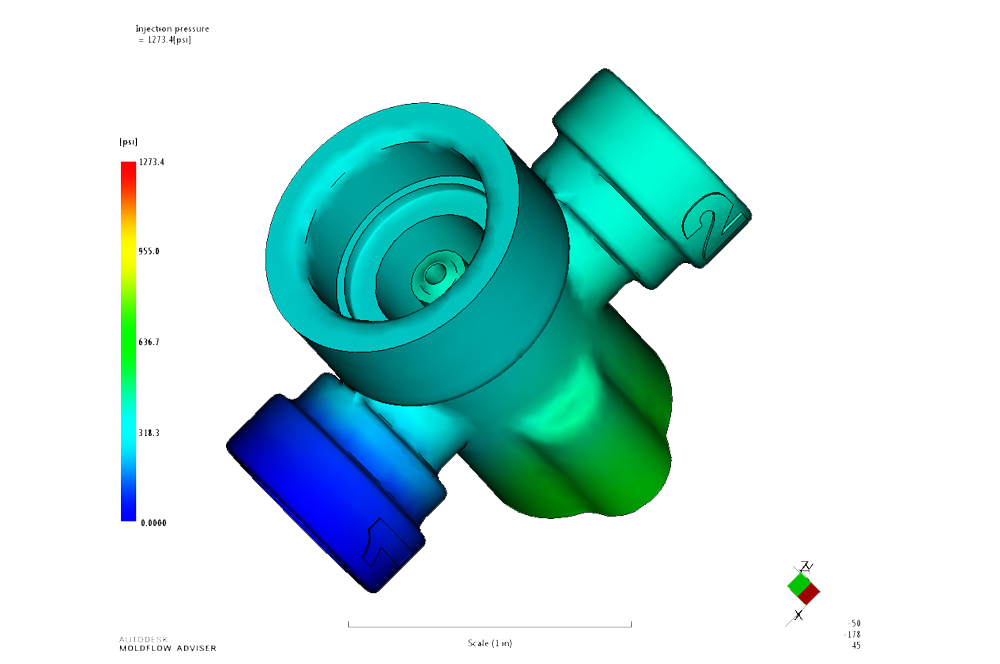

Read MoreIS MOLD FLOW ANALYSIS THE SECRET TO QUALITY INJECTION MOLDED PRODUCTS?

When it comes to injection mold manufacturing, the old adage that time is money has never been more true. On an increasingly competitive international stage, the ability to bring products to market on-time and on budget can often mean the difference between becoming a market leader and trying to play catch up against the competition.…

Read More3 REASONS WHY YOU MIGHT NOT NEED IN-HOUSE TOOLING AFTER ALL

Arguments abound touting the benefits of in-house mold tooling capabilities. But does the reality live up to the hype? The short answer: Not necessarily.. 1. THE TRICKLE DOWN EFFECT The longer answer is that, while many shops claim their in-house mold tooling can reduce your time to market, help you avoid downtime for repairs and…

Read MoreNEW OPPORTUNITIES FOR 3D PRINTING AND SHORT RUN PRODUCTION

Rapid prototypers around the globe have been utilizing 3D printing to create manufacturing prototypes that help prove out design concepts and test part functionality. But rapid prototyping is only the beginning when it comes to the opportunities that are now available for 3D printing. What else can 3D printing do for your business? Well, for…

Read More

Molding services for Agricultural customers

Molding services for Agricultural customers