Engineering

DISCOVER THE COST AND QUALITY BENEFITS OF KASO’S RETOOLING SERVICES

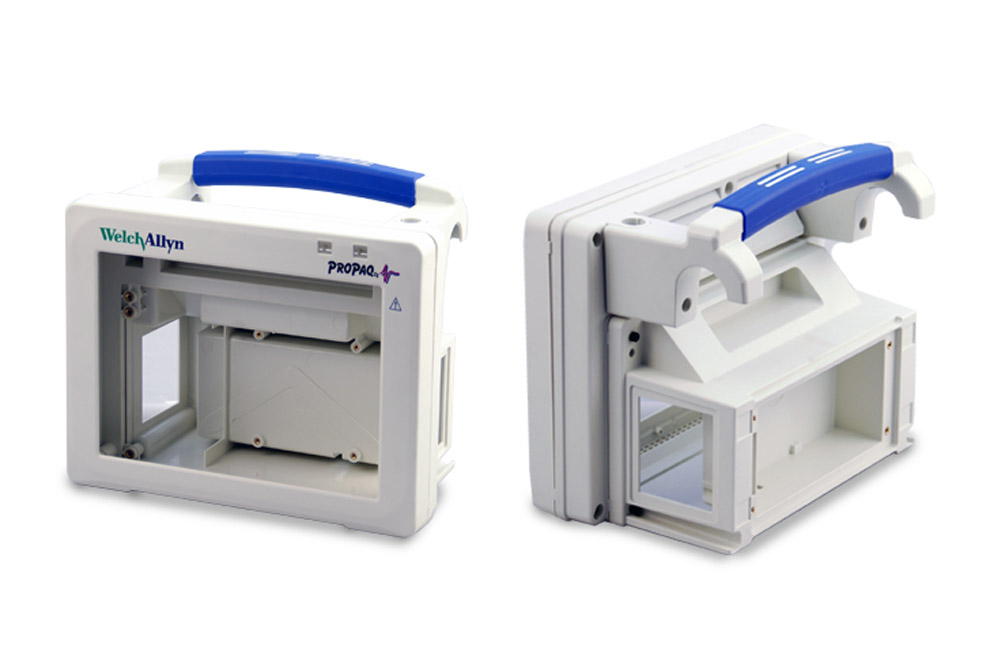

INJECTION MOLDING RETOOLING For many businesses, the word “retooling” can often cause feelings of anxiety and worry. People often picture expensive processes that slow project production times while inversely ratcheting up costs. As you may already know, injection mold tooling is often the most expensive aspect of a new injection molding project. The good news for businesses…

Read MoreRAPID PROTOTYPING AND 3D PRINTING: VIDEO INTERVIEW WITH KASO ENGINEERING MANAGER TIM BAILEY

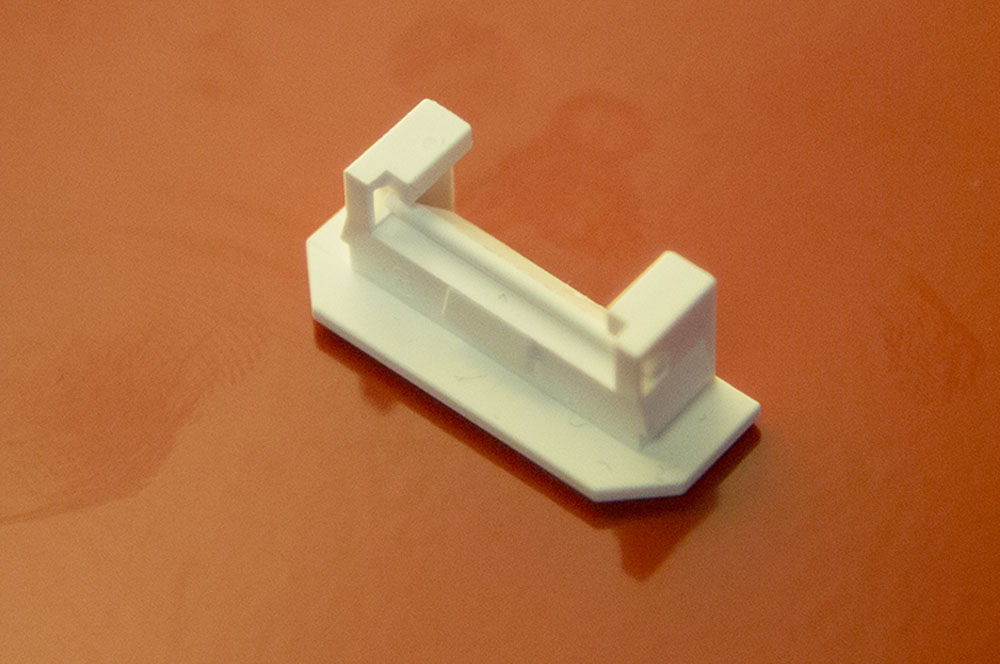

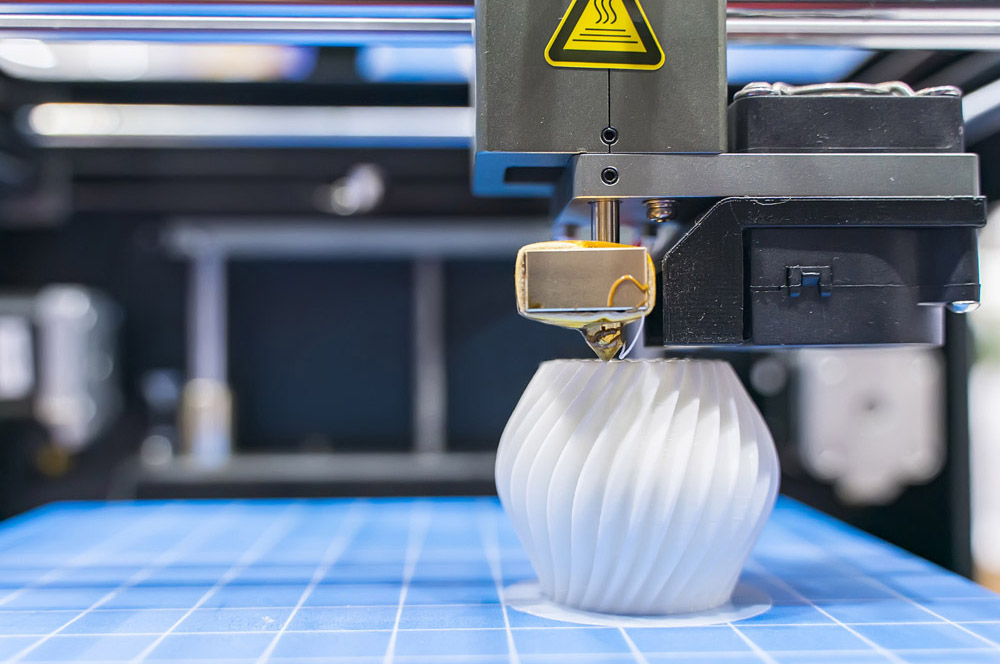

Rapid prototyping using 3D printing and FDM technology is one of KASO Plastic’s most popular engineering capabilities, and for good reason. In this short video, KASO Engineering Manager Tim Bailey explains the FDM 3D printing process and the ways rapid prototyping can help test part designs to avoid costly delays during production. Chosen because we…

Read MoreNEW KASO WHITE PAPER FOCUSES ON COST ADVANTAGES OF RAPID PROTOTYPING

We’re very excited to announce we have a new white paper available for complimentary download for KASO Plastics web visitors! The new white paper, “Save Money and Create Better Products Using Rapid Prototyping With 3D Printing” offers an inside look at the various technologies available for new product design prototyping as well as a step-by-step…

Read MoreDESIGNERS TURN TO PLASTICS TO LIGHTEN LOAD FOR AUTOMOTIVE PARTS

A November conference held in Livonia, Michigan highlighted a recent shift towards plastics in automotive part design and manufacturing. The move results in large part from growing government and consumer demand for automotive vehicles offering better emissions control and miles per gallon as well as overall product durability. In a recent post from Plasticsnews.com, it was…

Read More

Molding services for Agricultural customers

Molding services for Agricultural customers