Injection Mold Design

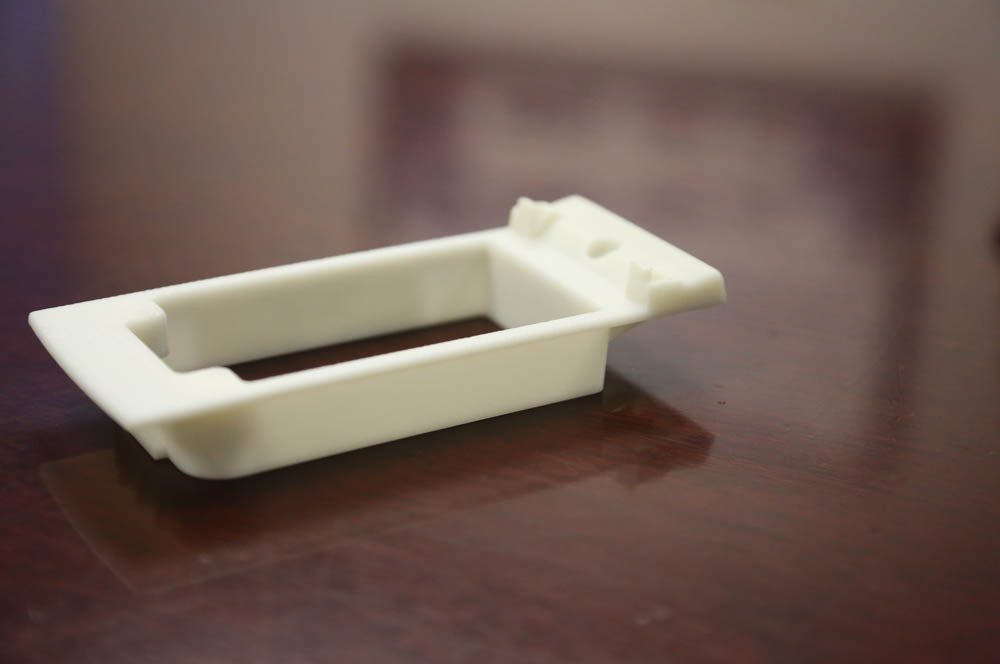

3D PRINTED INJECTION MOLDS: A NEW WAY TO TEST PRODUCT DESIGNS

3D PRINTED PROTOTYPES 3D printing has long been used to create prototypes that can test out product designs to ensure the fit and function of new parts, but recently it’s been gaining steam as an effective tool for creating injection molds as well. 3D PRINTED INJECTION MOLDS What is there to be gained by using…

Read MoreENGINEERING AND RAPID PROTOTYPING SERVICES AT KASO – INVESTING IN YOUR SUCCESS

KASO ENGINEERING SERVICES Productivity and profitability are two key factors for contract manufacturing success, and there are many methods that can be implemented to improve both. Productive management of your time and resources will help increase your profits while reducing any potential loss via design or manufacturing inefficiencies. KASO Plastics offers an opportunity for our…

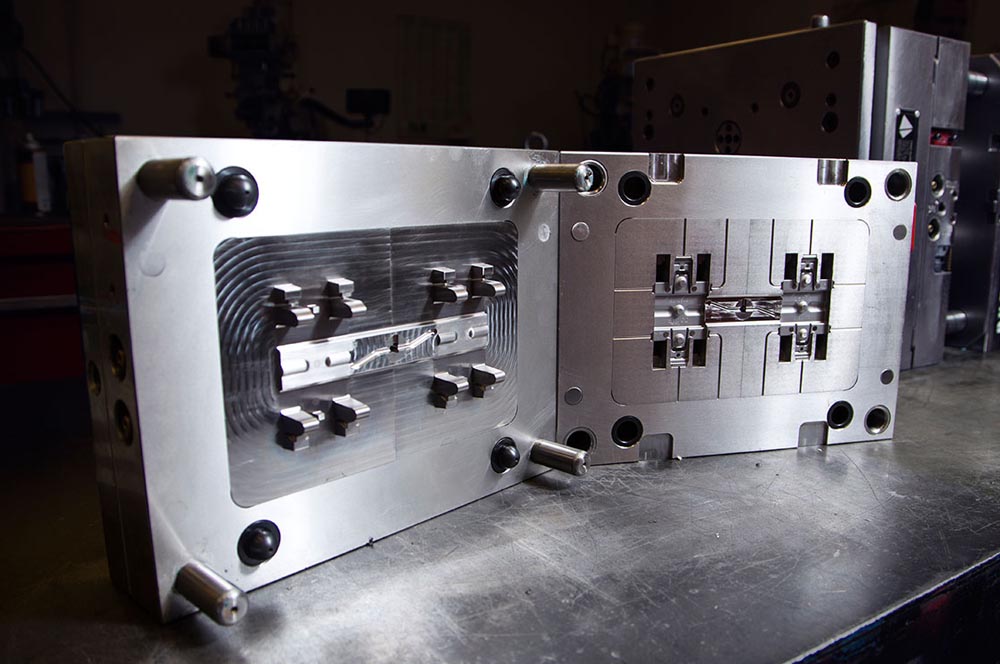

Read More3 REASONS WHY YOU MIGHT NOT NEED IN-HOUSE TOOLING AFTER ALL

Arguments abound touting the benefits of in-house mold tooling capabilities. But does the reality live up to the hype? The short answer: Not necessarily.. 1. THE TRICKLE DOWN EFFECT The longer answer is that, while many shops claim their in-house mold tooling can reduce your time to market, help you avoid downtime for repairs and…

Read MorePREPARE TODAY, GROW TOMORROW: RETOOLING HELPS BUSINESSES SCALE EFFECTIVELY

Growth happens. And when it does, your business may be faced with a real dilemma if you aren’t prepared to take on the additional capacity, leaving you out in the cold when it comes to enjoying those highly coveted economies of scale. Retooling can often be the solution to help your business grow more efficiently.…

Read More

Molding services for Agricultural customers

Molding services for Agricultural customers