Plastic Injection Molding

OUTSOURCED OR IN-HOUSE? WHAT YOU’LL NEED TO CONSIDER

CHOOSING BETWEEN IN-HOUSE OR OUTSOURCED INJECTION MOLDING As your business grows, there are certain adjustments you will have to make to adapt to greater demand. Perhaps you need to hire a few more full-time employees or invest in more sophisticated bookkeeping software. Although these changes may be difficult to get used to at first, they…

Read MoreWHAT YOU NEED TO KNOW ABOUT INJECTION MOLD MAINTENANCE

If you have a car, you already know the best way to prevent major issues is to invest in regular care and maintenance. This same principle holds true when it comes to your injection molds. These tools are not only expensive, but will also be used over and over again. Therefore, preventative maintenance on a…

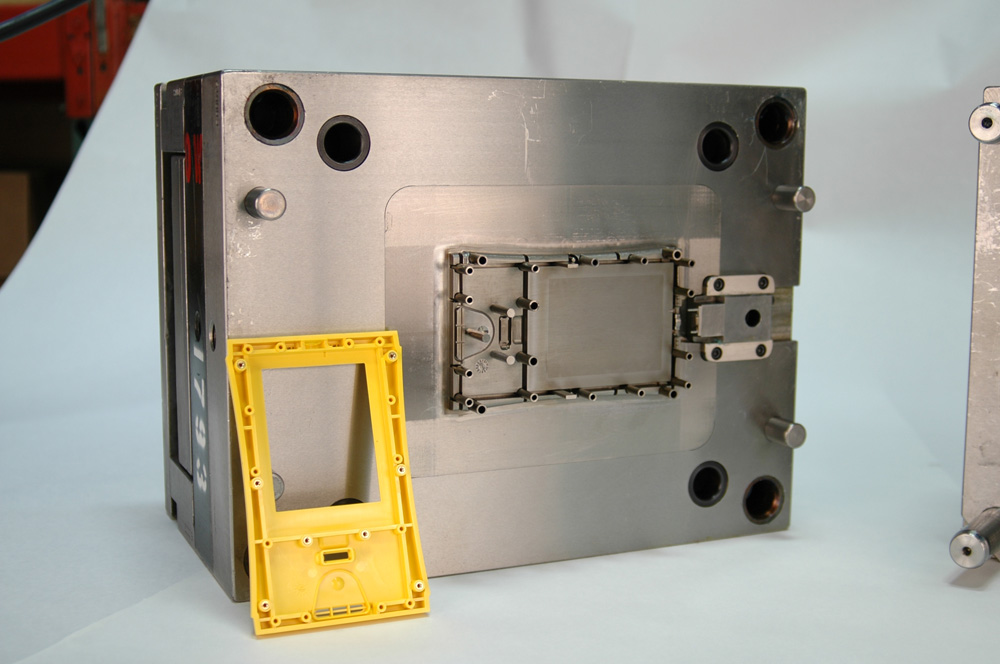

Read MoreWHY ARE INJECTION MOLDS SO EXPENSIVE?

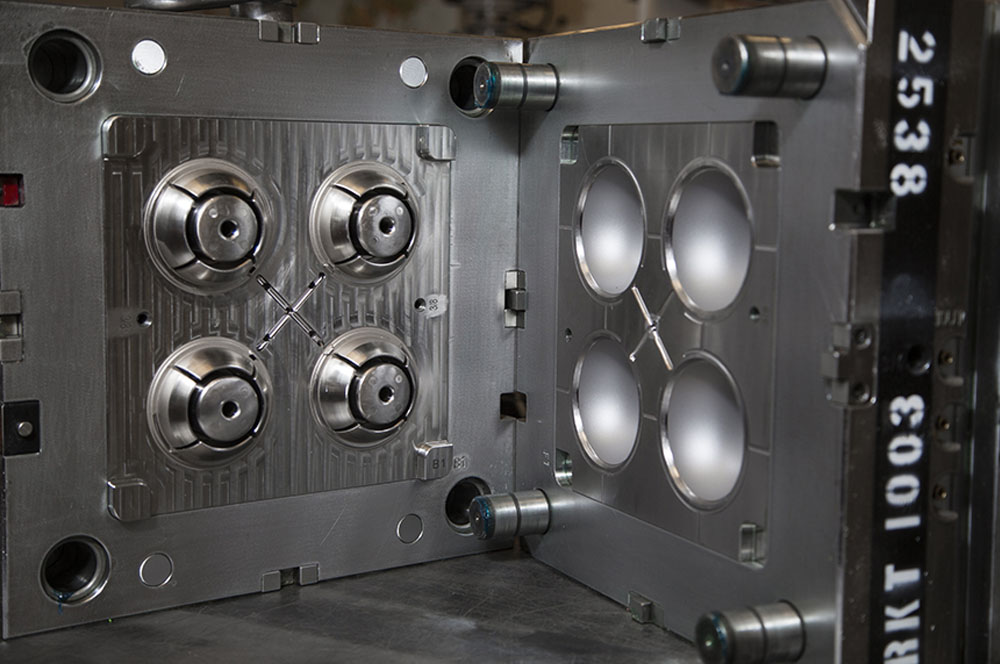

First-time product designers, we understand that the first look you get at how much your new product’s injection mold is going to cost can be… impactful. After all, the injection mold is the most expensive element of any new product launch. But why? Why are injection molds so dang expensive? INJECTION MOLD DESIGN AND TOOLING…

Read MoreSUCCESSFUL INJECTION MOLDING STARTS WITH THE RIGHT INJECTION MOLDER

In our more than 60 years, we’ve often met people who feel intimidated when it comes time to get started with plastic injection molding. Maybe it’s all the big machines, but–more likely–it’s the high costs often associated with getting started. There are initial upfront investments, of course; these include the design and creation of your…

Read More3 SIGNS IT’S TIME TO BREAK UP WITH YOUR INJECTION MOLDER

We know break-ups are painful. But much like that year in high school when you were dating Connie but actually interested in her friend Jessica, there are times when it’s just the right thing to do. THE PAINFUL TRUTH Often companies feel locked in once they’ve selected an injection molder, but the simple fact is…

Read MoreCHOOSING THE RIGHT INJECTION MOLDER

KASO Plastics understands how challenging it can be to find a quality injection molder. To make the decision-making process easier, we’ve provided a list of frequently asked questions we get here at KASO. You can use these questions to evaluate our team or other manufacturers to find the manufacturing partner that’s right for you. DOES…

Read MoreINJECTION MOLDED MEDICAL DEVICES LEAD GROWTH IN THE MEDICAL MARKET

Already a $56 billion industry in the United States, the Medical product market shows no signs of slowing in coming years, in particular due to the continued innovation in injection molded medical devices, according to a recent article published in PlasticsNews this month. While the medical market also includes unique challenges for manufacturers–strict FDA regulations, for one,…

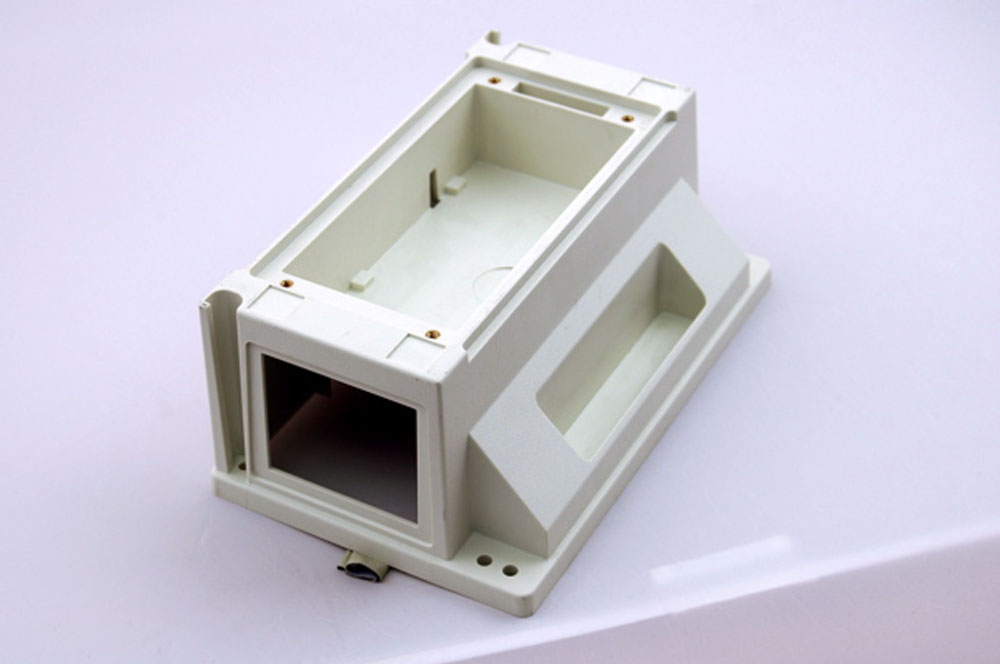

Read MoreKASO’S HIGH-TOLERANCE INJECTION MOLDING: A GOOD FIT FOR ELECTRONIC AND ELECTRICAL CONNECTORS

ELECTRICAL CONNECTOR INJECTION MOLDING Electronic and electrical connector injection molding is a capability offered by KASO for any of our clients across a wide range of industries, and for good reason. Electronic and electrical connector production requires a very high level of precision to complete the sometimes-intricate components. At KASO, our experienced engineers can assist…

Read MoreOVER MOLDING AT ITS BEST

QUALITY INJECTION MOLDING MACHINES With KASO’s new Arburg Vertical Clamp Injection Molding Machine, we are capable of completing precise molding tasks for specific projects and requirements. From PCB encapsulation to weatherproof cable over molding, and connector over molding to custom designs to suit any request. The Arburg 1200 T 1000-400 Vertical Clamp Injection Molding machine utilizes…

Read MoreLEARN MORE ABOUT KASO’S INDUSTRIAL INJECTION MOLDING CAPABILITIES

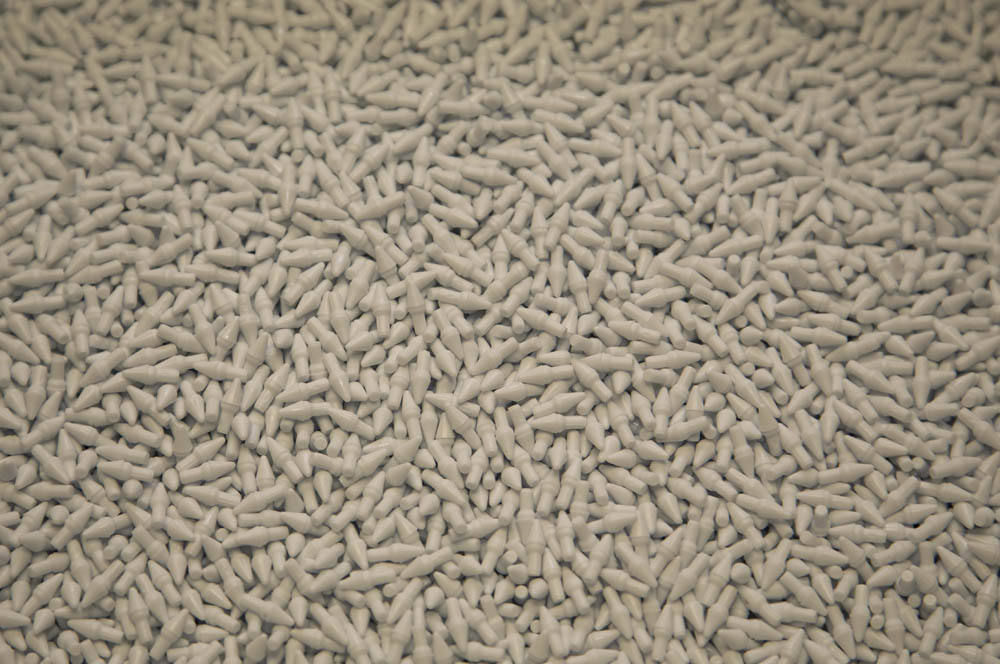

KASO’s wide range of plastic injection molding and other contract manufacturing capabilities serve a wide range of industries that includes many industrial markets. We have served the industrial automotive industry for more than 50 years, going back to KASO’s beginnings back in 1962, and our Engineering staff have as many years experience providing expert materials selection…

Read More

Molding services for Agricultural customers

Molding services for Agricultural customers