Posts Tagged ‘plastic injection molding’

An Update on Reshoring: Dissatisfaction Continues to Grow with Offshore Manufacturing

For decades, companies have turned to offshore manufacturing to meet shifting demands and cut production costs. Unfortunately, many companies are left feeling unhappy with their offshore manufacturing due to the often unpredictable and inconsistent quality of the items and components that are produced. This dissatisfaction has led to a shift among manufacturers who are beginning…

Read MoreWhat’s Next for Injection Molding

With another year making its way out the door, it’s a great time to reflect on where our industry is heading. Below are a few of the trends we believe will affect plastics professionals and consumers in the months ahead. The Search Continues for Lighter Weight Parts While not exactly a new trend, the search continues…

Read MoreHow We Can Make Injection Molding More Sustainable

If you use injection molding to produce plastic parts and components, it’s important to consider the ways in which your production affects the environment and what you can do to minimize the effects it has on the world around you. Here are just a few of the ways we can work together to make injection…

Read MoreTOP DESIGN CONSIDERATIONS FOR INJECTION MOLDING

Injection molding can be a great choice to create a wide variety of products. When it comes to injection molded products, the possibilities are virtually endless, but it’s essential to take some key factors into consideration during the design and development of your product to ensure the best possible end results. Wall thickness: One of the…

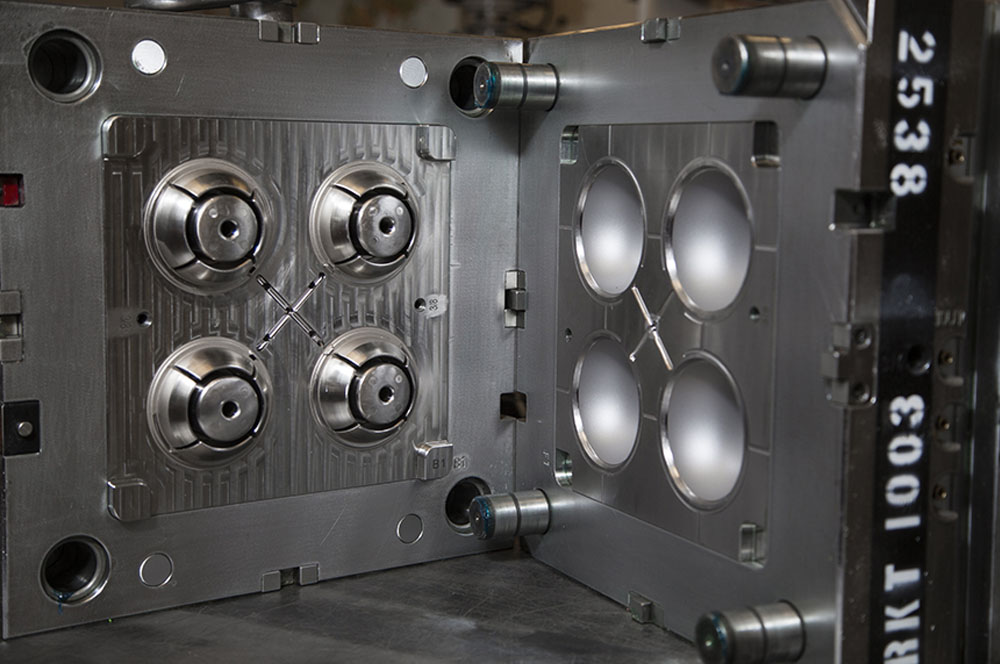

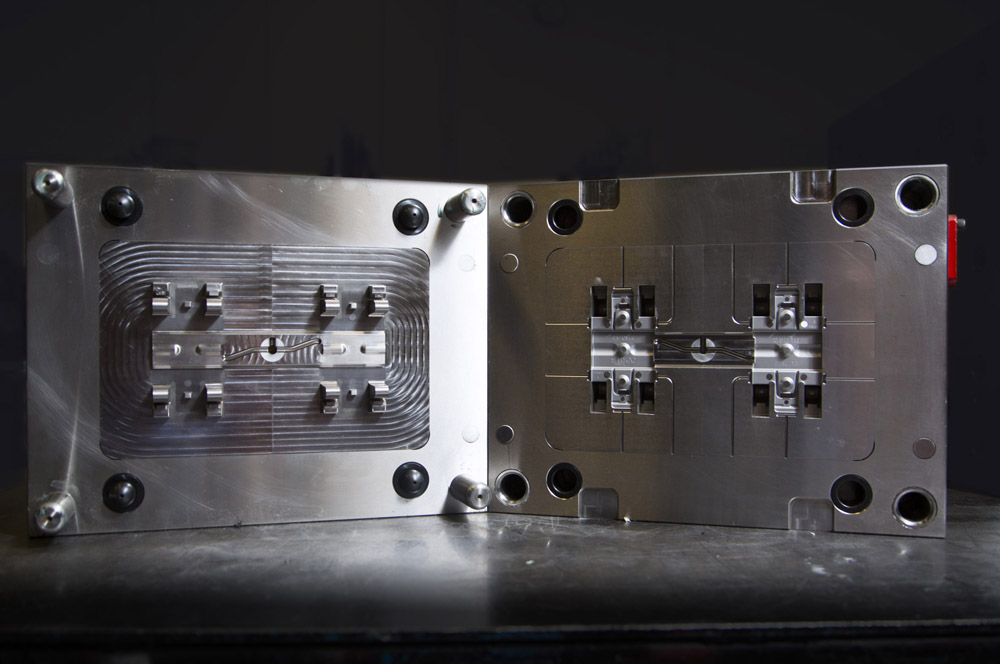

Read MoreWHAT FACTORS AFFECT THE PRICE OF AN INJECTION MOLD?

When you’re developing an injection molded part, there are a lot of factors to take into consideration. One of the most important things to consider is the price of your injection mold. This is dependant on a wide variety of different factors and it can fluctuate significantly depending on how those factors vary. Understanding the…

Read MoreWHY MORE OEM MANUFACTURERS ARE TURNING TO CONTRACT MANUFACTURING PARTNERSHIPS

When you’re designing and developing a product, your manufacturing strategy is essential to the overall success of your production. In recent years, an increasing number of OEM manufacturers have begun establishing partnerships with contract manufacturers to improve the quality of their products and streamline product development. There are several reasons why these OEM manufacturers are…

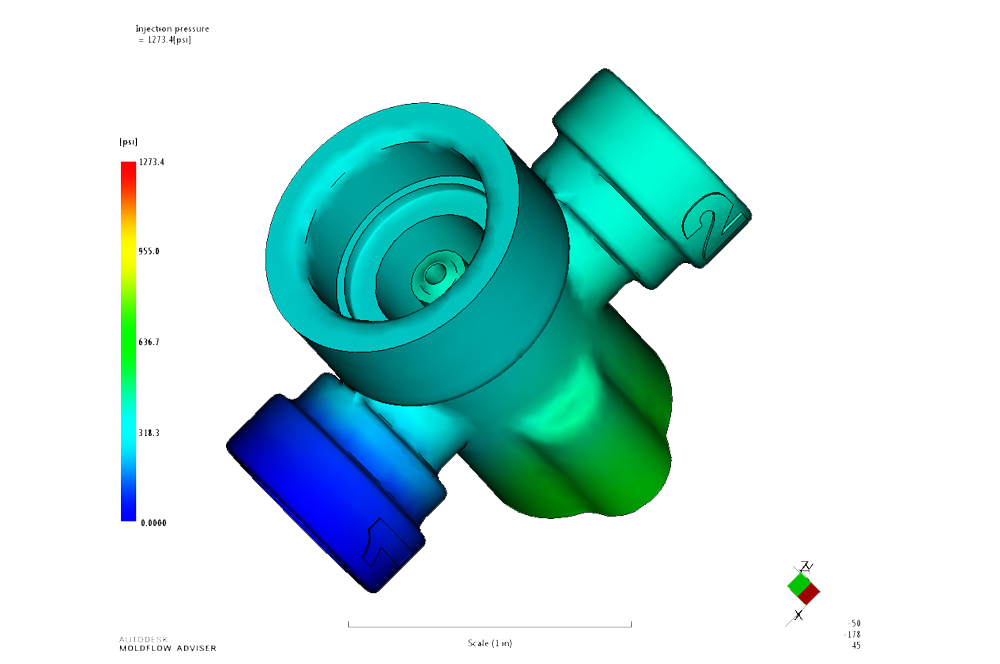

Read MoreIS MOLD FLOW ANALYSIS THE RIGHT CHOICE FOR ALL PROJECTS? HERE ARE A FEW THINGS TO CONSIDER.

Injection molding has advanced over the last few decades and the injection molding process continues to evolve and improve. One of the more important tools used in modern injection molding design is mold flow analysis. Mold flow analysis allows us to assess a mold’s design to ensure that it will deliver all of the strength,…

Read MoreA LOOK BACK AT OUR MOST POPULAR ARTICLES FROM 2018

If you follow KASO’s injection molding blog, you already know we publish articles that cover a wide variety of topics related to injection molding, product development, and injection mold engineering. And while all of our blog articles are intended to provide useful information you can use to improve your injection molding and product development experience,…

Read MoreTRENDS AFFECTING THE PLASTICS INDUSTRY IN 2019

As any new year begins, people speculate about what to expect in the coming months. Here are some of the trends affecting the plastics industry in 2019. Growth in automotive end-use applications: While injection molding has traditionally been utilized to create parts and components for machinery, equipment and industrial applications, we expect to see demand growing…

Read MoreCONSIDERATIONS FOR MATERIAL SELECTION

WHAT YOU NEED TO KNOW ABOUT MATERIAL SELECTION Material selection is aided by answering a few key questions about your product, so you can begin to narrow down your options. What will the product be used for? Is it going to get banged around, or is it mostly for a cosmetic application? How the part…

Read More

Molding services for Agricultural customers

Molding services for Agricultural customers