Posts Tagged ‘KASO Plastics’

COMMON ULTRASONIC WELDING ISSUES AND HOW TO AVOID THEM

Ultrasonic welding is a manufacturing process that joins two different materials (often metal and plastic) – through the application of high-frequency vibrations. This process is widely regarded for its efficiency, consistency and cost-effectiveness, but like many manufacturing processes, issues can arise. Understanding these potential problems before you get started–and knowing how to resolve them–can help…

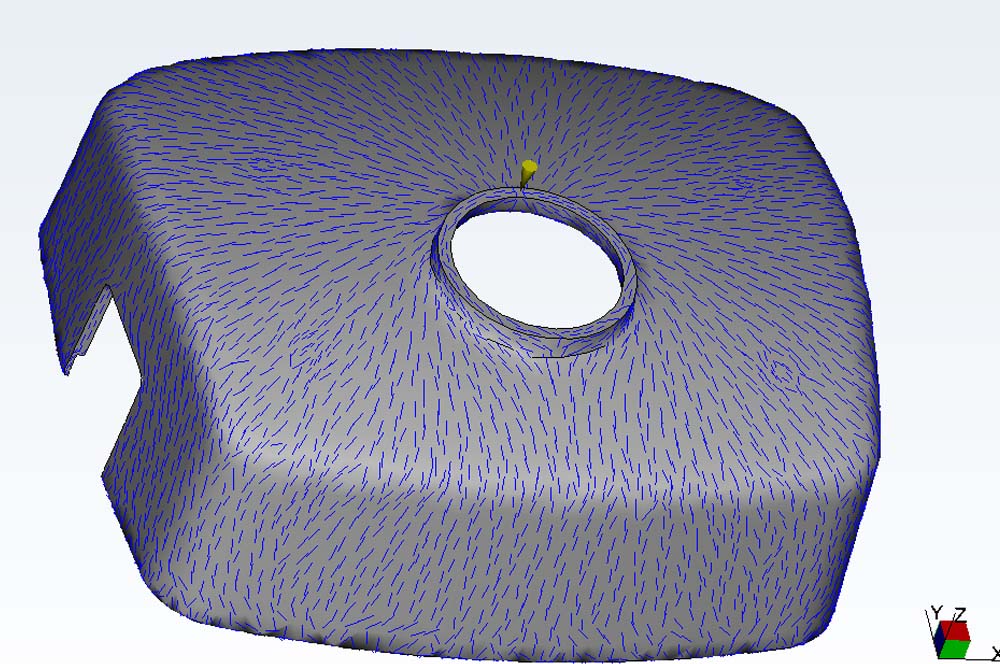

Read MoreTIPS FOR SUCCESSFUL INJECTION MOLD DESIGN

Injection molding isn’t a simple process, and as many of us know, it can sometimes take quite a bit of trial and error to get your injection molding designs just right. And while every new design requires several iterations between initial conception and production, there are several things you can do now to increase the…

Read MoreWHY AUTOMATION IS TRENDING IN THE INJECTION MOLDING INDUSTRY

These days, it seems like automation is progressively changing the structure of most industries. Even highly specialized processes are beginning to make the shift to automation. In the injection molding industry, this shift can only be categorized as a revolution, one that is changing nearly every step of the injection molding process. Although these changes…

Read MoreSTRUCTURAL FOAM MOLDING: FREQUENTLY ASKED QUESTIONS

Keeping up with all of the different injection molding processes that are around can be a challenge. All have distinct features, but you might have a hard time determining exactly which one is right for your products. If you need to manufacture more durable structural components, you might consider structural foam molding, a process that…

Read MoreEVERYTHING YOU NEED TO KNOW ABOUT OVERMOLDING

Overmolding is an injection molding process that involves the combination of multiple materials to form a single part. This process makes it possible to create dynamic components that combine the best qualities of different materials for unique applications. There are several different benefits of overmolding that clearly explain why it’s become an increasingly popular process…

Read MoreIS GAS ASSIST INJECTION MOLDING THE RIGHT CHOICE FOR YOUR PRODUCTS?

As the injection molding industry has evolved, new methods and procedures have been developed to increase product quality. Gas assist injection molding is an injection molding process that uses nitrogen gas to create hollow channels within a mold. As the nitrogen gas forces material away from the core and out toward the edge of the…

Read MoreOUTSOURCED OR IN-HOUSE? WHAT YOU’LL NEED TO CONSIDER

CHOOSING BETWEEN IN-HOUSE OR OUTSOURCED INJECTION MOLDING As your business grows, there are certain adjustments you will have to make to adapt to greater demand. Perhaps you need to hire a few more full-time employees or invest in more sophisticated bookkeeping software. Although these changes may be difficult to get used to at first, they…

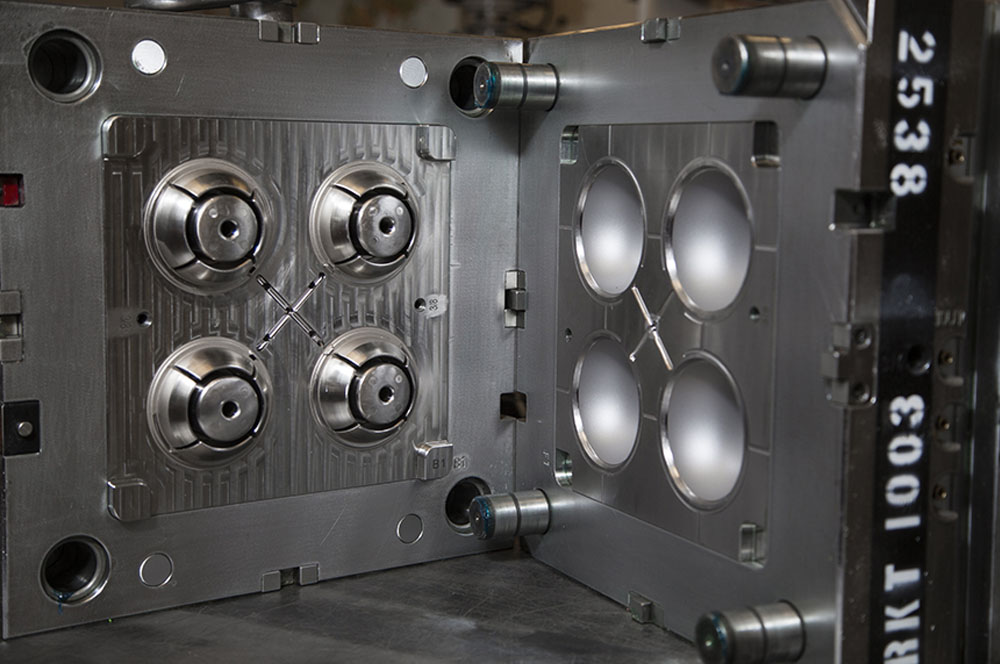

Read MoreWHAT YOU NEED TO KNOW ABOUT INJECTION MOLD MAINTENANCE

If you have a car, you already know the best way to prevent major issues is to invest in regular care and maintenance. This same principle holds true when it comes to your injection molds. These tools are not only expensive, but will also be used over and over again. Therefore, preventative maintenance on a…

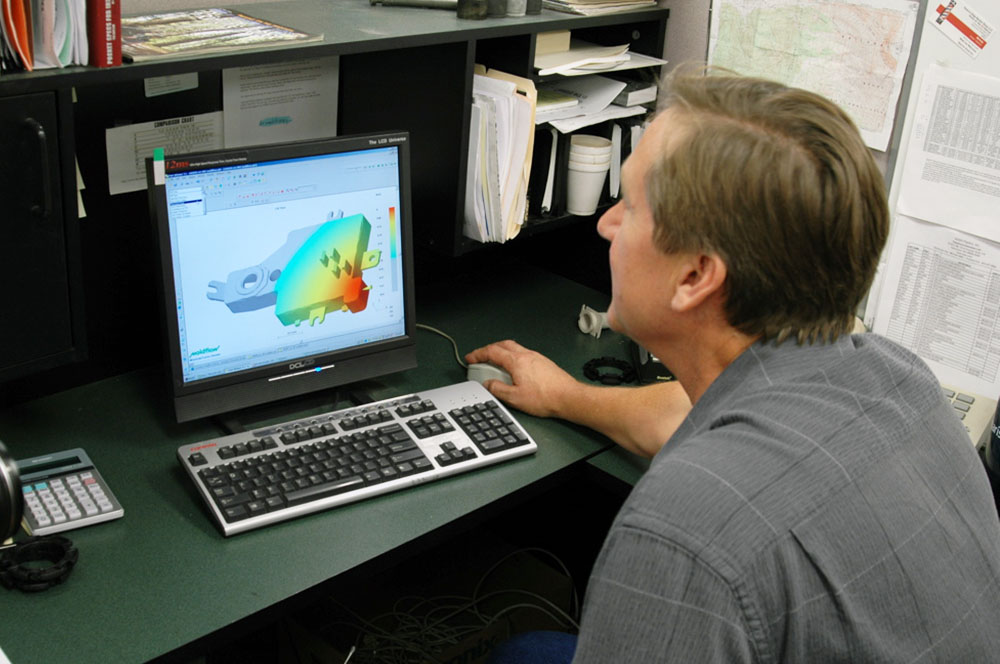

Read More5 THINGS TO CONSIDER IN THE DESIGN FOR MANUFACTURING REVIEW

THE DESIGN FOR MANUFACTURING REVIEW The Design for Manufacturing review is intended to maximize the quality and performance of your parts and help you control your production costs. This is helpful for large and small-scale manufacturing alike, and is most effective in the beginning stage of product design and production. DFM allows you to improve…

Read MoreULTRASONIC WELDING OR THERMAL HEAT STAKING? HOW TO CHOOSE THE RIGHT METHOD

Plastic components are frequently integrated into other manufactured products as a way to reduce cost and create lighterweight goods. It’s an excellent choice for creating strong, flexible parts. In order to maintain the integrity of these plastic parts, metal components may be inserted into the plastic housings, primarily using ultrasonic welding or heat staking for…

Read More

Molding services for Agricultural customers

Molding services for Agricultural customers