Posts Tagged ‘KASO Plastics’

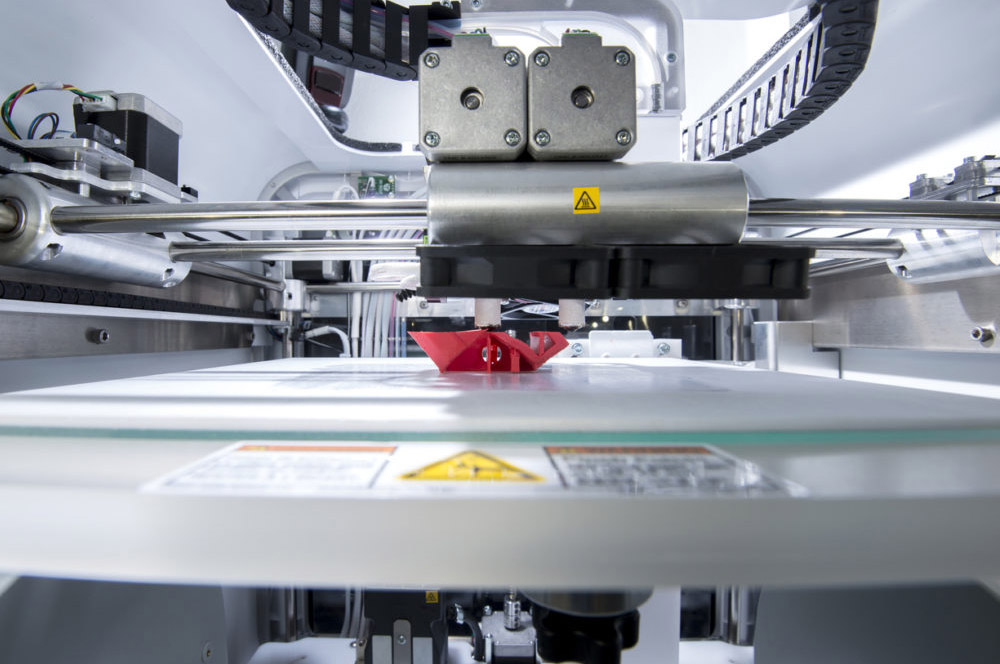

IT CAN DO WHAT?! NEW PLASTICS MANUFACTURING APPLICATIONS FOR 3D PRINTING

3D printing is an exciting technology that has only continued to grow more refined and sophisticated since its original iteration back in 1993. In recent years, we have seen it used for everything from prototype manufacturing to 3D-printed shoes. The opportunities that 3D printing technology has opened have had huge impacts on a number of…

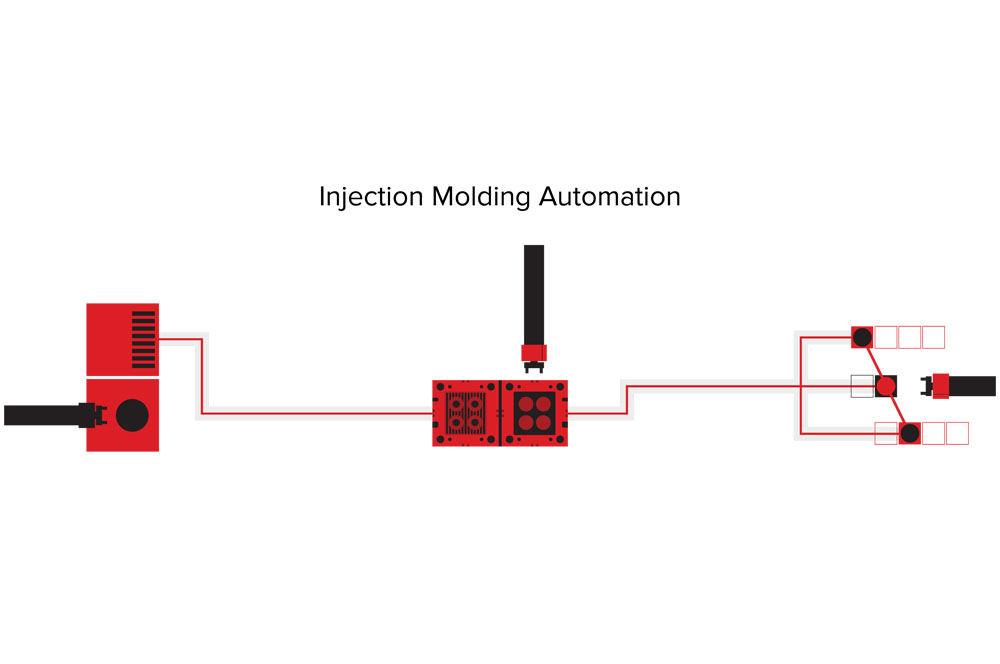

Read MoreNEW WHITE PAPER EXPLORES OPPORTUNITIES FOR BRINGING AUTOMATION TO INJECTION MOLDING

AUTOMATION AS A COMPETITIVE TOOL After years of watching U.S. manufacturing move overseas to countries with low labor costs and seemingly endless capacity, the U.S. reshoring movement has officially begun. No longer content to suffer from the faulty production, miscommunication, and long lead times often associated with outsourced production, today’s product developers are looking for…

Read MoreYOUR BUSINESS BENEFITS WHEN YOU CHOOSE LOCAL

Over the last several decades, there has been a major shift towards foreign manufacturing. From garments to electronic devices, it seems as though many items on the market today were made somewhere other than the United States. Exporting manufacturing jobs has had significant impacts on the American economy, but it also has implications for day-to-day…

Read MoreKASO UPDATES INJECTION MOLDING FACILITY AND EQUIPMENT

KASO PLASTICS INVESTS FOR OUR CUSTOMERS For nearly 60 years, KASO Plastics has provided our customers with plastic injection molding and engineering expertise. Over those decades, we have continued to develop and improve our processes to ensure that every one of our clients receives work that meets a high standard of quality. The attentive service…

Read MoreAS TECHNOLOGY CONTINUES TO EVOLVE, DEMAND FOR EMI AND RFI SHIELDING GROWS

ELECTRONICS EVERYWHERE Over the last few decades, technological advancements have made an incredible impact on our society. From the electronic systems integrated into Aerospace equipment to the smart phone that you use every day, electronic and digital infrastructure is all around us. And even though all of this new technology has enhanced connectivity, promoted advancements…

Read MoreIN HONOR OF NATIONAL MANUFACTURING DAY: MANUFACTURING TRENDS TO GET EXCITED ABOUT

October 6th is National Manufacturing Day, a day set aside to celebrate modern manufacturing and inspire the next generation of workers to get excited about new opportunities and trends in manufacturing. Manufacturing is changing, and it’s important for us to help ‘set the record straight’ when it comes to some of the misperceptions people have…

Read MoreWHY ARE INJECTION MOLDS SO EXPENSIVE?

First-time product designers, we understand that the first look you get at how much your new product’s injection mold is going to cost can be… impactful. After all, the injection mold is the most expensive element of any new product launch. But why? Why are injection molds so dang expensive? INJECTION MOLD DESIGN AND TOOLING…

Read MoreSO WHY IS MATERIAL SELECTION SO IMPORTANT, ANYWAY?

When it comes to your plastic parts, you hear a lot about the importance of material selection. And, while it can seem confusing at first, the truth is proper material selection can make a BIG difference for your products. Here’s why. DIFFERENT MATERIALS, DIFFERENT COSTS Now you might be thinking surely there are plenty of…

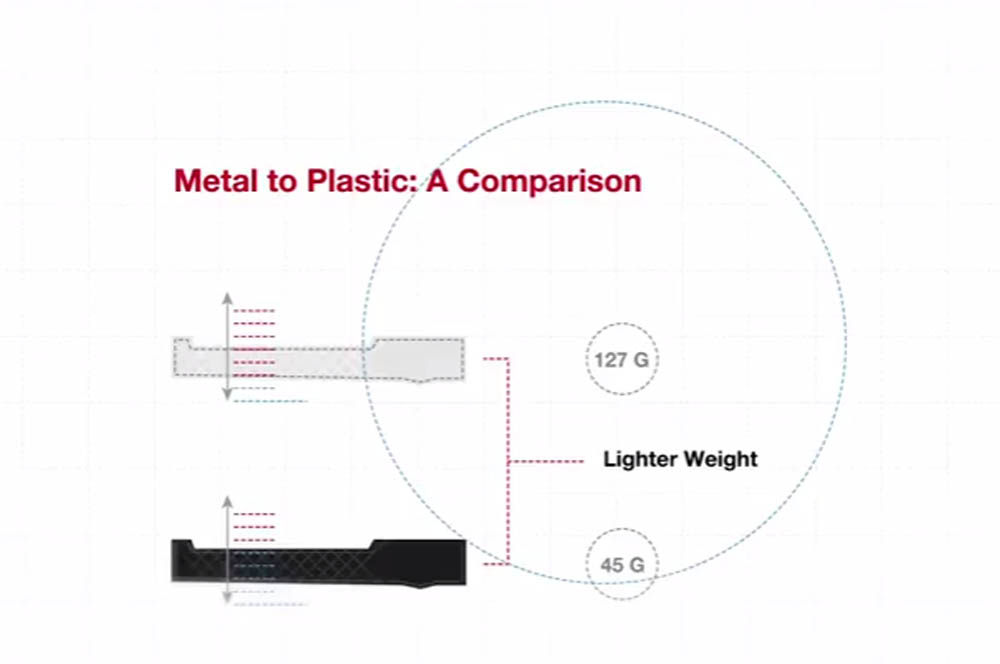

Read MoreNEW VIDEO EXPLORES THE BENEFITS OF METAL TO PLASTIC CONVERSION

A LIGHTER WEIGHT SOLUTION Metal to plastic conversion can provide a host of benefits for many metal parts, offering a lighterweight solution without sacrificing the strength and integrity of your important product components. METAL TO PLASTIC CONVERSION VIDEO In the short video below, you can learn more about the metal to plastic conversion process at…

Read MoreSUCCESSFUL INJECTION MOLDING STARTS WITH THE RIGHT INJECTION MOLDER

In our more than 60 years, we’ve often met people who feel intimidated when it comes time to get started with plastic injection molding. Maybe it’s all the big machines, but–more likely–it’s the high costs often associated with getting started. There are initial upfront investments, of course; these include the design and creation of your…

Read More

Molding services for Agricultural customers

Molding services for Agricultural customers