Posts Tagged ‘plastic injection molding’

NEW WHITE PAPER: FIND COMPETITIVE ADVANTAGE WITH EARLY SUPPLIER INVOLVEMENT

The growing global marketplace has placed additional strain on product developers who are faced with the challenges of getting new products through product development and onto market faster than ever before. One solution is the Early Supplier Involvement process, where product designers and manufacturers get the opportunity to review product designs and leverage the combined resources of…

Read MoreMOLD FLOW ANALYSIS: EARLY STEPS TO BETTER PRODUCT DEVELOPMENT

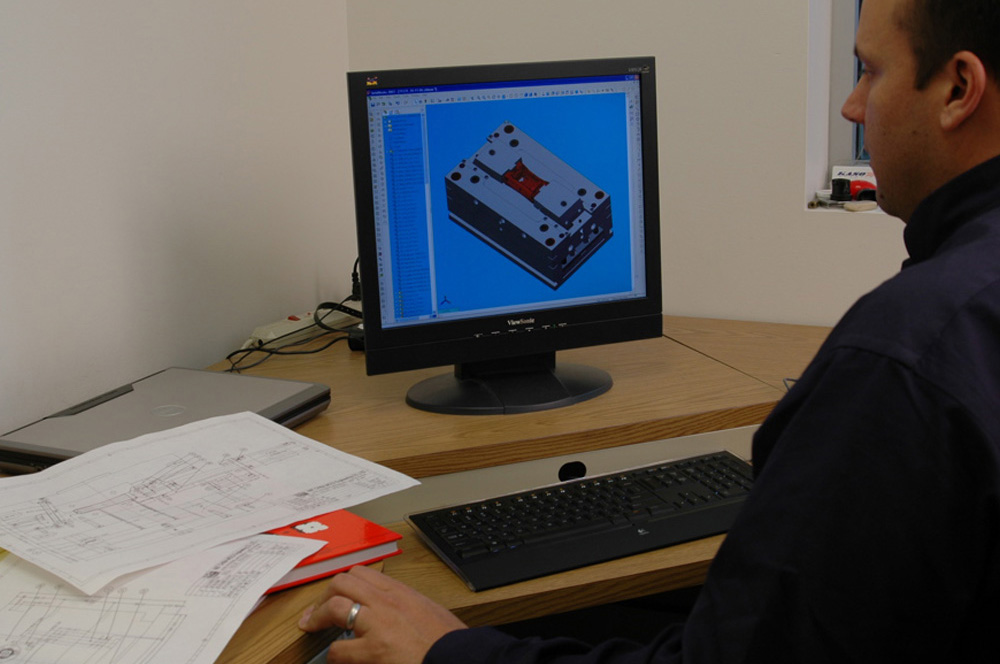

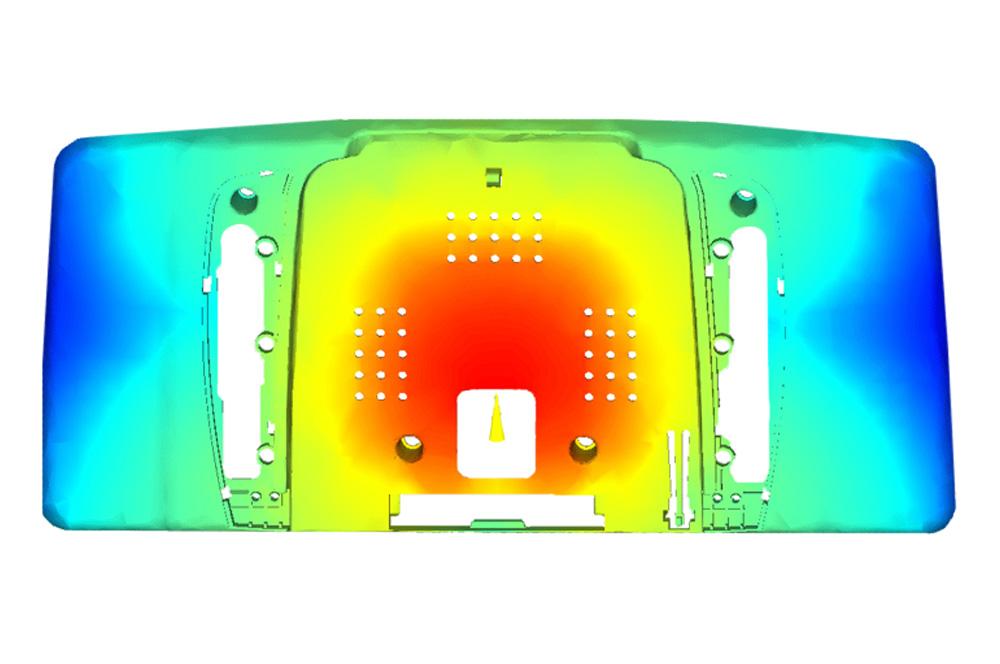

OPTIMIZING TO SAVE YOU MONEY Mold flow analysis is the virtual study optimization and of key injection molding attributes such as pressure profile, time to fill, melt temperature, and mold flow points that take place before any actual injection mold tooling or production begins. This enables evaluation and insight into the performance and function of…

Read MoreOVER MOLDING AT ITS BEST

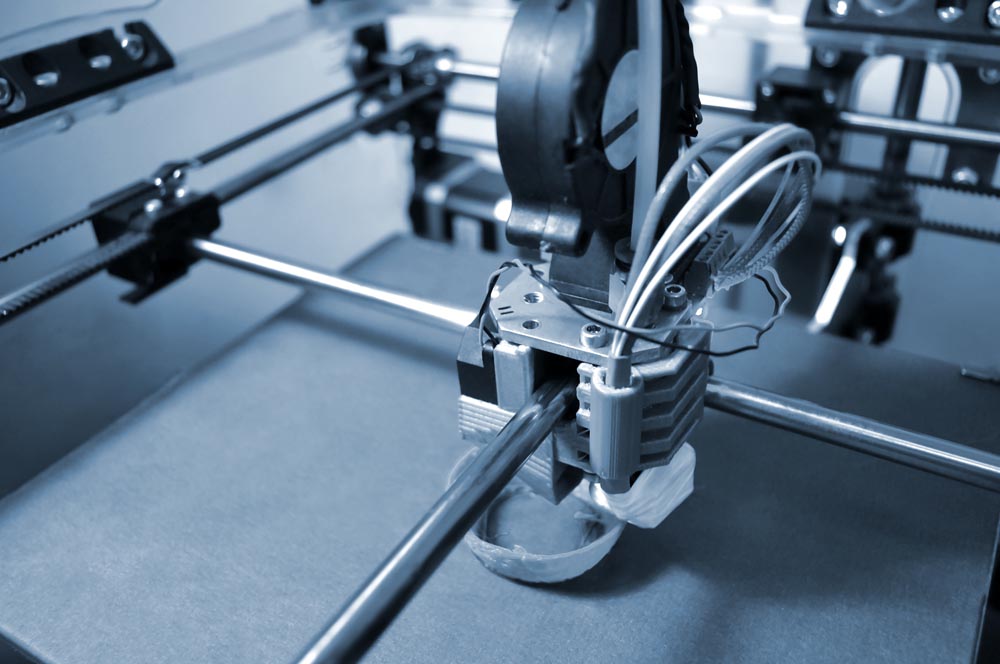

QUALITY INJECTION MOLDING MACHINES With KASO’s new Arburg Vertical Clamp Injection Molding Machine, we are capable of completing precise molding tasks for specific projects and requirements. From PCB encapsulation to weatherproof cable over molding, and connector over molding to custom designs to suit any request. The Arburg 1200 T 1000-400 Vertical Clamp Injection Molding machine utilizes…

Read MoreKASO INVESTS IN NEW ARBURG VERTICAL CLAMP INJECTION MOLDING MACHINE

To ensure our company maintains a competitive edge in the injection molding industry, KASO Plastics frequently invests in new capital equipment to ensure our continued ability to produce high quality products at competitive prices. To start off the new year, we’ve recently invested in a new Arburg 1200 T 1000-400 Vertical Clamp Injection Molding machine.…

Read MoreGROWTH OF AUTOMOTIVE MARKET BRINGS GOOD TIDINGS FOR INJECTION MOLDERS

This past year, the automotive market saw an increase of 4%, the biggest single increase since back in 2002. This is great news for injection molders acting as suppliers for automotive manufacturing, according to a recent article published on plasticsnews.com, and helps explain the 17% increase in sales for automotive molders in 2012. But what else does…

Read MoreEND OF 2013 SEES RISE IN NEW PLASTIC INJECTION MOLDING EQUIPMENT SHIPMENTS

And that’s good news for the plastics industry across the board, as companies gear up on new capital equipment to meet rising demand for plastic injection molded parts and components in 2014. The new report, filed by a special branch of the Society of the Plastics Industry (SPI), provides new data from Q3 2013 that…

Read MoreDESIGNERS TURN TO PLASTICS TO LIGHTEN LOAD FOR AUTOMOTIVE PARTS

A November conference held in Livonia, Michigan highlighted a recent shift towards plastics in automotive part design and manufacturing. The move results in large part from growing government and consumer demand for automotive vehicles offering better emissions control and miles per gallon as well as overall product durability. In a recent post from Plasticsnews.com, it was…

Read MoreMETAL TO PLASTIC PART CONVERSIONS – DISCOVER A LIGHTER WEIGHT SOLUTION TO METAL PARTS

Aware of basic benefits gained from metal to plastic conversion, OEMs have been converting heavier metal parts into lightweight plastics for years. But what these same manufacturers may not know is that, as technology improves and new materials continue to improve, the number of parts suitable for conversion continues to grow as well. Advantages to converting…

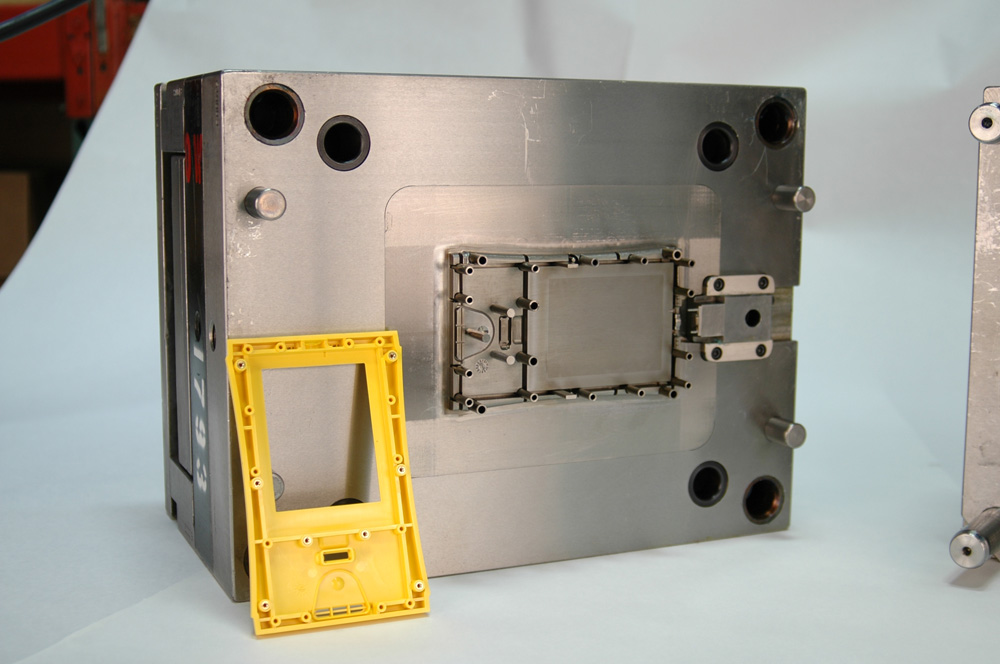

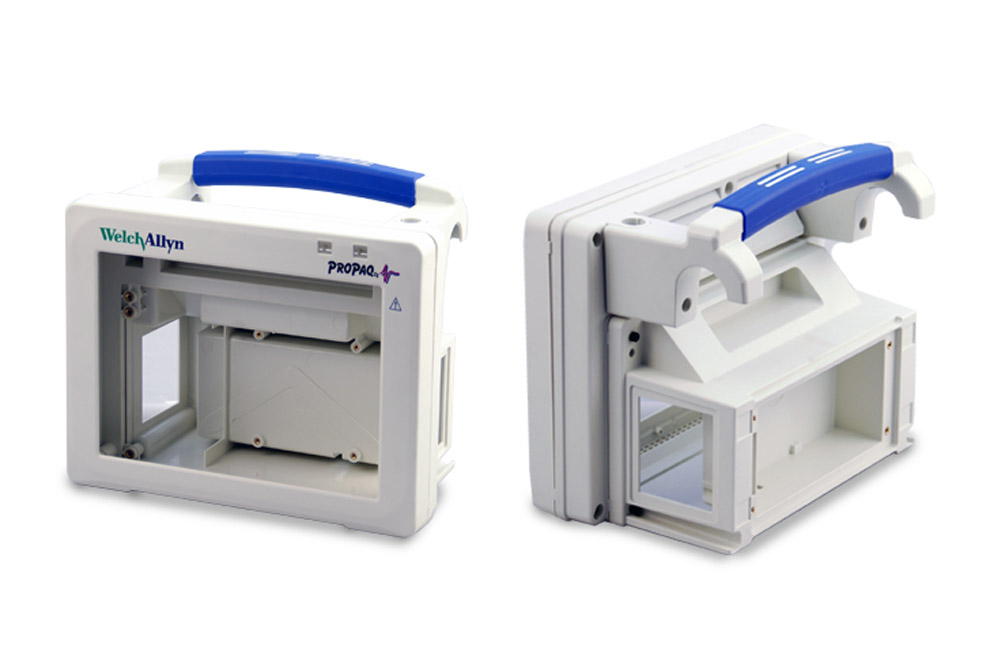

Read MoreRED CROSS WORKERS ASSESS DISASTER DAMAGE USING HIGH-TECH PRODUCTS MANUFACTURED BY KASO

In times of disaster, getting information from those on the scene to the organizations that can send help is one of the most crucial steps involved in making sure people get much-needed relief. Visit msnbc.com for breaking news, world news, and news about the economy That’s why the Red Cross uses special high-tech PDA devices designed by KASO…

Read MoreNEW REPORT SIGNALS ROSY 2012 FOR MOLDMAKERS

Results from a recent Winter 2012 Business Forecast Survey presented by the American Mold Builders Association are in… and things are looking good! With almost half of moldmakers who responded expecting an increase in business in 2012, rising employment and increasing profits, all signs seem to predict the positive growth that began in 2011 will…

Read More

Molding services for Agricultural customers

Molding services for Agricultural customers